Mineral Deposit Sampling Techniques

Mineral Deposit Sampling Techniques

source https://www.ausimmbulletin.com/feature/increasing-value-through-best-practice-sampling-quality-assurance-and-quality-control-in-gold-mining/https://www.minecogroup.com/blog/practical-exploration-geology-i-underground-channel-sampling

http://www.appliedminex.com/decrep/general/fiexover.htm

https://www.alsglobal.com/industries/oil-_and_-gas/upstream/core-analysis/petrography/thin-section-preparation

https://gulfsci.usgs.gov/tampabay/photo/leaders/photos2.html

https://www.azomining.com/Article.aspx?ArticleID=55

https://www.geologyforinvestors.com/diamond-drill-hole-drilling/

Rock Sampling

Trench/Adit Mapping

Core Sampling / Drilling

see

also Diamond Drilling (in field skills...)

Rock Sampling

Rock sampling reveals the true potential of an area for containing a

mineral deposit. An anomaly in a rock sample from bedrock has had no

effects of secondary dispersion, so the location of the sample is the

location of the source. A rock sample anomaly will provide much more

valuable information about the location of the mineral deposit because its

source is within the mineralizing system, ie, it helps delineate the zone

of primary dispersion. However, this applies only to rock samples

collected from bedrock. Rock samples of float (rock material suspended in

colluvium with no indication of proximity to the bedrock source), talus,

glacial material, etc... give no indication of location of the source, so

even if they are highly mineralized, they are of limited value. Rubble

(rock material suspended in colluvium and due to consistency or other

information suggests proximity to the bedrock source) in some cases may be

worthwhile to sample.Several different types of rock samples are collected for mineral exploration. Most importantly, rock samples are collected to determine the concentration of metals, including both the major and trace metals. This type of sample is most commonly referred to as a “geochem” sample. Trace metal values are often useful as “pathfinders”, which means they are closely associated with the metal of interest and may occur within a halo surrounding the mineralization of interest.

Rock geochem samples are collected in different manners depending on the goal of the sampling.

The principle types include:

- Grab Samples: A grab sample is a sample of rock material from

a confined area (< 30cm across). It can be a single piece of rock.

These are the most common types of samples collected. If it is not

specified otherwise, one usually assumes that is the sample type. The

sample usually consists of a single piece of rock, or chunks, which

are representative of a specific type of rock or mineralization

.

.

- Composite Samples: A composite sample consists of small chips of uniform rock material collected over a large area (generally > 2.5m across). These are the ideal “representative” samples. The procedure is to collect small pieces of rock over a large area (usually at least 10 feet across) and to make the sample as homogenous as possible. A composite sample might be collected to determine the background values of trace elements in a particular type of rock, or to determine if ore grade mineralization is present over a large area.

- High Grade Samples: A high grade sample consists of selective pieces of the most highly mineralized material, in which an effort is made to exclude less mineralized material. Consequently, a high grade sample is generally not representative of the overall mineralization type. A high grade sample might be collected to get an idea what the best possible values are, or to provide material for certain types of trace element analyses. If a such a selective sample does not return good results, then it is unlikely that valuable mineralization is present. When a high grade sample is collected it is important to note that it is a high grade sample so its values will not be misinterpreted as representing the “average” values.

- Chip Channel Samples: A chip channel sample consists of small

chips of rock collected over a specified interval. The objective is to

obtain the most representative sample possible for the specified

sample interval. Most of the time chip channel samples are collected

in succession along a sample line which is laid out in advance using a

tape. This provides a great deal of information about the width and

other aspects of the geometry of a mineralized zone. Often the chip

channel samples are collected along the floors or walls of trenches or

adits. When chip channel sampling along walls, sometimes a piece of

canvas or plastic is laid out for the material to fall on so as to

avoid contamination and make the collection easier. The freshest

material possible is sampled, preferably chipping directly from

bedrock. Sample intervals are set at a specified width, usually

ranging from 30cm to 7m. For example, in a five foot interval, at the

end of the first foot, 20 % of the sample bag should be filled, at the

end of the second foot the bag should be filled to 40 %, etc... Due to

the method of sampling, chip channel samples tend to be rather large

(up to 20 pounds for a five foot interval)

.

.

- Whole Rock Major Oxide Samples: Whole rock major oxide

samples are most often collected to study the whole rock geochemistry

of plutonic and volcanic rocks. The sample must be completely fresh,

unweathered, and unoxidized. If necessary the weathered rind must be

removed by chipping or by using a rock saw. Samples must also be

unaltered by hydrothermal alteration (this adds new components and

removes others, such that it will no longer represent the parent magma

composition). The sample is analyzed for the principle oxides,

including, SiO2, Al2O3, CaO, Fe2O3, FeO, K2O, MgO, MnO, Na2O, P2O5,

TiO2. Usually at least 98 % of the rock is made up of minerals

comprised of some combination of these components. Not uncommonly

igneous rocks contain up to 1 % water. This water is lost when the

rock is oxidized in the furnace (referred to as LOI or “loss on

ignition”). Major oxide analyses are used to classify igneous rocks

based on their chemical composition. These can be used to compare

intrusions within a district or to use in regional studies by

comparing the analyses with those for known models.

- Age Date Samples: Age date samples are used to determine

the age of the rocks. There are several methods, including 40Ar/39Ar,

U/Pb, K/Ar, Rb/Sr, and Carbon 14. They are all based on the half life

theory, which states that certain isotopes of certain elements decay

to radioactive daughter products at a specific rate, called a decay

constant. Knowing the constant, the amount of parent and daughter

product material in the sample is measured and then used to calculate

the age of the rock. The 40Ar/39Ar method can provide reliable age

dates up to several hundred million years. Argon gas forms by decay of

potassium and gets locked in the crystal lattice. The U/Pb method is

also quite reliable, and can be used to date rocks up to billions of

years old. Older rocks have longer histories, and during those longer

histories more events can occur which cause problems. For example,

metamorphism and tectonic activity. These can cause opening of the

crystal lattice of the mineral being dated, and loss of the daughter

product material, causing erroneous results. Typically these effects

cause the methods to yield ages which appear to be younger than the

actual age of the rock. Minerals can also obtain overgrowths during

remelting events, causing excess parent material to be present, also

making the rock appear younger. Ar-Ar and U-Pb age dates can be

obtained can be obtained from very small amounts of material. The

procedure involves separating the grains of one mineral type to be

dated. Ar-Ar age dates are usually obtained on minerals such as mica

or hornblende. U-Pb age dates are usually obtained on zircon or other

accessory minerals which are known to contain small amounts of

uranium.

- Petrographic samples are collected to conduct thin section

petrographic analysis of the rock, which is the identification

and evaluation of the minerals comprising the rock by using a

microscope equipped with both plane and polarized light. A thin

section is made of the rock, which is a paper thin slice of the rock

mounted on a glass slide. Different minerals have different optical

properties when the plane light or polarized light is transmitted

through the thin section. Textural relationships also become apparent,

which provides information about the order of crystallization (or

paragenesis). The proceedure is to cut a flat side and use special

epoxy to glue the piece of rock called a plug, to the glass slide.

Thin a special trim saw cuts off the part opposite the glass. Then the

rock wafer is polished with special grinders to achieve the desired

thickness. The thickness must be very precise to compare the optical

properties with known standards.

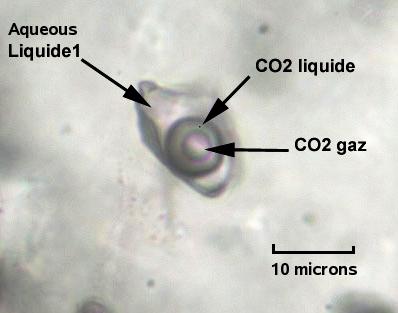

- Fluid Inclusion: Fluid inclusion samples are typically

samples of quartz (others include fluorite, sphalerite or tourmaline).

The samples are prepared similar to a thin section, and examined using

a special microscope equipped with a heating stage. The inclusions can

contain solid, liquid or gas, or any combination of these. The

inclusions are formed when they are trapped on the surface as a new

layer of the mineral crystallizes. As the mineral cools down, the

phases separate. The sample is heated gradually while being examined

under the special microscope to find the temperature at which the gas

or solid crystal in the fluid inclusion will goes back into solution.

This provides valuable information about the temperature and pressure

of formation of the ore forming fluids.geologists routinely envisage

tectonic, sedimentary and metamorphic events which are no longer

active and should also envisage the palaeo-fluid systems which led

directly to the economic ore bodies that are now exploration targets.

A bit more about fluid inclusions

Typical studies of fluid inclusions are myopic and too often fail to see beyond the minute details of individual fluid events and do not scale to be usable as exploration methods. University tuition concentrates so much on forensic analysis of a few inclusions in a few samples from a hydrothermal system that it fails to show how to use fluid information in mineral exploration where we need to examine a large spatial array of samples to determine a favourable mineralised target location. Fluid inclusions are "bubbles" of fluid trapped within the host mineral during its deposition from its parent hydrothermal fluid. They are tiny remnants of the exact fluid from which the host mineral and its associated ore minerals deposited and they provide direct information about the fluid composition, temperature and pressure at which the hydrothermal deposit formed. They are usually very small, from 1 to 20 microns across so you need a microscope at high magnification to study them. They are surprisingly abundant and milky quartz typically contains some 1 billion fluid inclusions per gram! Most fluid inclusion studies are carried out on quartz, simply because it is transparent, but inclusions occur in all hydrothermal minerals.During the active deposition of the hydrothermal minerals, the parent fluid is usually a single phase, most likely a supercritical aqueous fluid with salt and perhaps CO2 at high temperature and pressure. But when the fluid cools it will probably condense to liquid water with a vapour bubble, CO2 may form a separate phase if it is abundant and salt may crystallise as halite if it exceeds the saturation level of 23% NaCl. Observations of the complex phase relations are used to deduce the original deposition temperature, pressure and salinity in genetic studies of ore deposits.

The most common fluid inclusions contain simply water, now condensed to liquid with a bubble of water vapour. From these, the original deposition temperature can be deduced, but that is not particularly useful in mineral exploration unless you have a large array of samples with which to map out palaeo-thermal anomalies. These images are at a much higher microscope magnification of about *400.Many fluid inclusions contain substantial amounts of CO2. This is very useful in mineral exploration as mineral deposits, such as gold, are frequently associated with such CO2 rich hydrothermal fluids. If the internal pressure of the inclusion is high enough (above about 50 bars), CO2 can be present as a liquid phase at room temperatures (below 31 C)And if the hydrothermal fluid is highly saline, above 23% NaCl, then halite can crystallise upon cooling, with other additional solid crystals also present. Such fluids usually occur in porphyry copper deposits or the core of igneous intrusion derived fluid systems. Although such saline inclusions are less common, they can be very useful in mineral exploration.

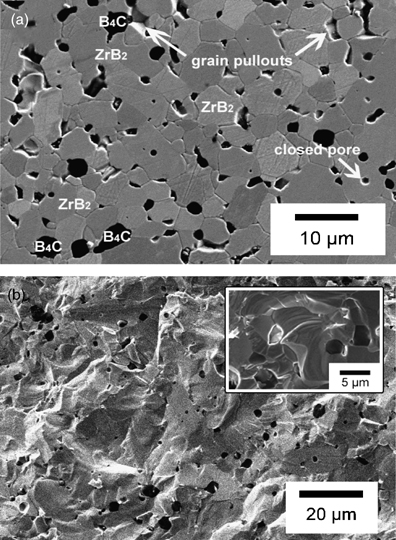

- Polish Section: to look at reflected light properties of ore

minerals; ie, sulfide and oxide minerals.

- Electron Microprobe Analysis: highly sophisticated method to determine mineral compositions and textures using the backscattering of electron beams.

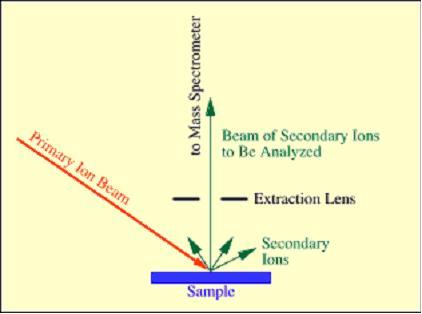

- Secondary-ion mass spectrometry (SIMS) is a technique used to analyze the composition of solid surfaces and thin films by sputtering the surface of the specimen with a focused primary ion beam and collecting and analyzing ejected secondary ions. The mass/charge ratios of these secondary ions are measured with a mass spectrometer to determine the elemental, isotopic, or molecular composition of the surface to a depth of 1 to 2 nm. Due to the large variation in ionization probabilities among different materials, SIMS is generally considered to be a qualitative technique, although quantitation is possible with the use of standards. SIMS is the most sensitive surface analysis technique, with elemental detection limits ranging from parts per million to parts per billion.

Trench/Adit Mapping

Trench or adit mapping is the process of creating a geologic map, which shows the geology of the floor and walls of the trench or adit. Adit mapping emphasizes mapping of the walls more than the floor because the floor is often poorly exposed due to the presence of a layer of debree which results from blasting and mucking. Trench mapping emphasizes floor mapping because:- the floor is usually scraped as clean as possible with a dozer or backhoe, and

- because floor mapping shows a “map view”. Trench or adit mapping always involves setting up a base line using a tape. Meter marks are then painted or flagged and labeled.

- The base line and distance marks are then drawn to scale on the map page to facilitate mapping. Often the same base line is used to accomplish a chip channel sampling program.

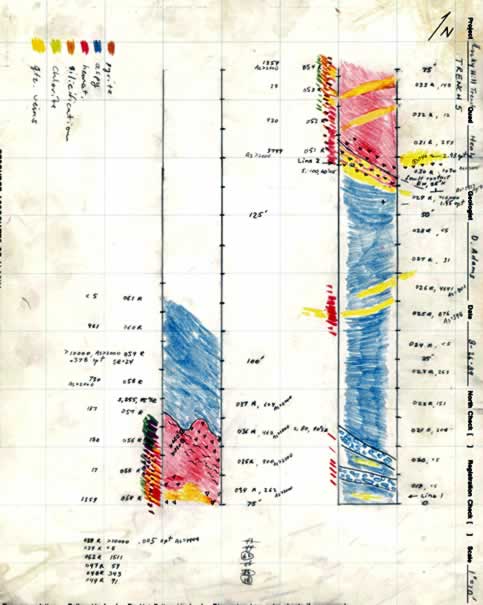

One approach is to first draw the outline of the floor, which will be oriented with respect to true north and drawn to scale. The geology of the floor is then mapped just as an ordinary geologic map is made. The corner of the trench or adit matches the edges of the strip showing the geology. This is the “map view” (looking straight down) of the geology of the floor. The edges of the “strip map” represent the two bottom corners of the trench. The walls of the trench or adit are mapped adjacent to the strip map such that the right wall is mapped as if looking at the vertical on the right, and the left wall is mapped as if looking at the vertical wall on the left. These can be labeled to indicate they represent the geology of the walls, even though it is usually obvious. This gives a 3-D perspective of the geology, which greatly facilitates the interpretation of the geometry of features. For example in determining the dip of layers, faults, joints, etc... on the floor of the trench, it is useful to show where the feature trends as it intersects the adjacent walls. Structural measurements can be put directly on the map, in notation form next to the appropriate distance mark.

Another simpler approach used to make mapping more rapid is to sketch the floor outline at a standard, average width and not worry about the exact width. The outline is drawn parallel to the edge of the map sheet without regard to actual geographic orientation. The azimuth of the axis of the trench or adit floor is carefully measured and noted on the map. If the trench or adit contains bends, then the new orientation is noted at the appropriate distance mark on the map.

The alteration style can be added to one side or the other of the map if desired. The alteration can be mapped using colors, patterns or other designators, in the same way the rock types are mapped.

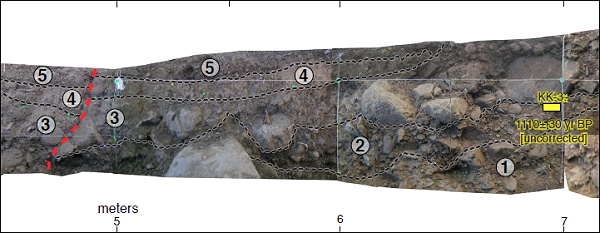

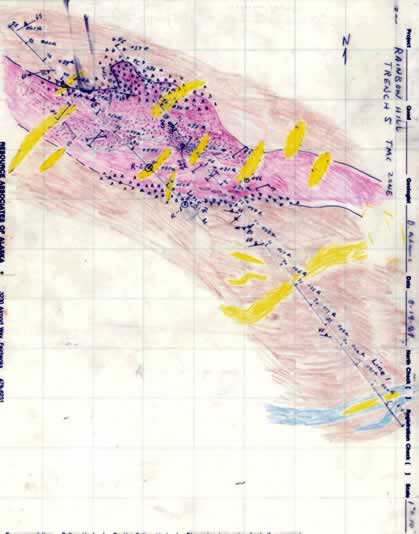

Example of Trench map oriented to true north.

Example of Trench 5 map with trench axis parallel with map page edges.

Core Sampling

Diamond drilling has directly resulted in the discovery of many minable orebodies that would otherwise have gone untapped. Before the introduction of mainstream diamond drilling, mining was still primarily dependent on finding outcrops of rock, with little information available about ore concentrations below the surface. Diamond drilling allows the removal of solid cylinders of rock (core) from deep within the earth.

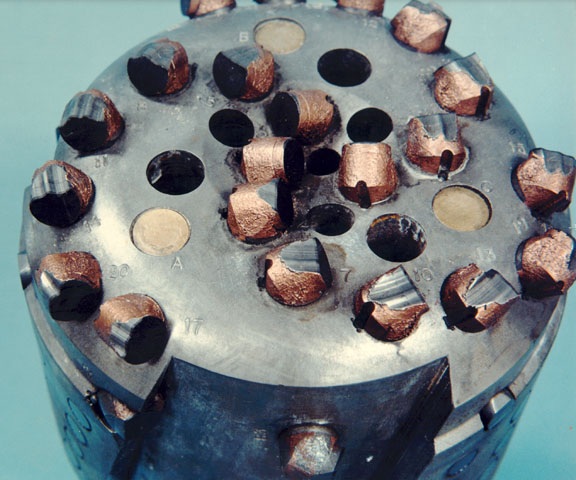

Drill Structure

Diamond core drilling is so called because it uses a ‘diamond bit’. This drill bit is composed of group of small, industrial grade diamonds set into a metallic, soft matrix. As the ground is drilled, this matrix will wear away and expose more diamonds.

This is then attached to a drill rod, which is around 10 foot in length, and then more sections of pipe can be attached to the top of this so a greater depth can be drilled. The depth that is drilled to is estimated by the number of rods attached to the top of the drill rod.

Inside the drill rod, a core tube is attached to a cable via a latching mechanism. The core tube is lifted to the surface using the cable, so the solid core can be removed.

There are two primary types of diamond drilling-rotary drilling and wineline drilling. Rotary drilling is used primarily for bore hole drilling, whereas wineline drilling is used for solid core sampling.

There a five standard tube sizes associated with wire line drilling. These are as follows:

- AQ (Hole diameter: 48mm)

- BQ (60mm)

- NQ (75.5mm)

- HQ (96mm)

- PQ (122.6mm)

The drill size used depends on the desired core diameter and the desired depth of drilling, and the wider the diameter of the tube, the more power that is required to drive the drilling.

A drill bit with industrial diamond cutters in a matrix. Image Credit: http://www.sandia.gov

Core Extraction

To extract core, the drill rod rotates the diamond bit, spinning it into the ground. As the drill bit bores through the rock, solid rock is taken into the circular opening at the end of the bit, into the core tube, and can then be recovered at the surface as it piles up. Once the core is recovered at the surface it is broken along natural fractures and stored in core trays to await analysis. A standard core tray can hold around 3m of core.

To keep the drill moving through the rock smoothly, the drill must be well lubricated using water to prevent overheating or sticking.

For optimum core extraction, the driller must listen to the drill to evaluate subsurface conditions. To keep drilling efficient, the rotation speed, pressure and water circulation must be strictly monitored.

Sometimes when drilling in highly fractured zones, overheating can occur due to a stuck bit. This issue is usually counteracted by the injection of mud or sawdust to plug fractures in the rock.

Applications

Diamond core finds its primary function in the exploration mining sector. It is usually one of the last stages of exploration, during which the orebody is delineated in three dimensions. This will determine whether the prospect is economically viable. Using a diamond drill rig, long vertical sections of core can be extracted from deep in the ground, which can then be analysed at the surface by geologists.

The core can then be analysed using a wide range of petrologic, structural and mineralogical techniques to determine whether the potential mining site is economically viable.

Extracted core is first washed and macroscopic features are logged by an exploration geologist. The core is then cut and representative samples are sent for chemical analysis.

Health and Safety

Mine sites always have inherent safety risks and diamond drilling rigs are no exception. While operating a diamond drill rig, correct protective gear must be worn at all times. Steel toe cap boots, hearing protectors, gloves, and goggles are some of the typical pieces of protective clothing needed.

When approaching an active drill rig, care must be taken to catch the drillers’ attention before stepping into the work area, as not to surprise the operator.

Furthermore, as diamond drilling is primarily an exploration technique, the conditions in which it is carried out are often harsh and so due diligence needs to be taken whilst in these environments. For example, if working in desert conditions, enough water and shelter must be provided for the drillers to prevent dehydration and heat stroke.