Tin Deposits

Tin Deposits

source http://www.ga.gov.au/data-pubs/data-and-publications-search/publications/aimr/tinhttp://www.australianminesatlas.gov.au/education/fact_sheets/tin.html

http://www.alexstrekeisen.it/english/pluto/greisen.php

Geological Setting of Tin Deposits

Associated metals

Mining

Australia

Bolivia

Brazil

Thailand

Malaysia

Indonesia

China

England - Cornish tin

Geological Setting of Tin Deposits

Cassiterite (SnO2) is the primary ore of Tin thisIt is found in hydrothermal veins and pegmatites associated with granite intrusions.

As a granititic intrusion reaches the final stages of cooling, the last, water rich , low temperature liquid concentrates on its top.

Tin, as cassiterite, having a low melting point is one of the last metals top come out of solution into a vuggy quartz rich crystal mesh called a greisen.

Greisen, commonly, are granitoid rocks in which >90% of the feldspar is repleaced by quatz, mica, topaz, cassiterite and other minerals.

Greisen, sometimes capped by pegmatite, forms near the roof of some granite plutons, and commonly hosts workable - though not always currently economic - Sn - W - Mo ore bodies.

The type of metal deposit correlates closely with the type of granite and the source rocks from which the magma formed.

Greisen is formed by self-generated alteration of a granite and is a class of endoskarn.

It means that greisen in most cases formed inside the granitic pluton itself that provided heat and hydrothermal fluids to initiate the greisenization.

Greisen occurs typically in belts or veins that intersect granite, and it passes into granite at the outer edges of these.

The transition between the two rocks is gradual, indicating that the greisen has been produced through alteration of the granite by vapours or fluids rising through fissures.

Greisen Alteration facies

Incipient greisen (granite): muscovite ± chlorite, tourmaline, and fluorite.

Greisenized granite: quartz-muscovite-topaz-fluorite, ± tourmaline (original texture of granites retained).

Massive greisen: quartz-muscovite-topaz ± fluorite ± tourmaline (typically no original texture preserved). Tourmaline can be ubiquitous as disseminations, concentrated or diffuse clots, or late fracture fillings. Greisen may form in any wallrock environment, typical assemblages developed in aluminosilicates.

Because of its durability tin is also frequently found concentrated in alluvial placer deposits, sometimes in large enough quantities to be commercially exploitable.

Cassiterite is by far the most important tin ore, although small amounts of tin are recovered from sulphide minerals such as stannite (Cu2FeSnS4) but they are more difficult to process.

Primary deposits can occur within the granite or within pegmatities or aplites (dyke like rocks) associated with the granite. They occur also in rocks surrounding the margins of the intrusive rocks as veins, disseminations, skarns or carbonate replacements generated by tin bearing fluids derived from the granite magmas.

Secondary deposits (placers and residual concentrations ) derive from the weathering and erosion of primary tin deposits. Since cassiterite is chemically resistant, heavy and so readily forms placer of residual concentrations.

Three kinds are:

- Eluvial Deposits Eluvium: refers to tin minerals concentrated by in situ weathering or weathering plus gravitational movement (sub-vertical or vertical) or accumulatio

- Colluvial Deposits Colluvium: refers to tin minerals concentrated in unconsolidated sediments that have been deposited at the base of hillslopes by either rainwash, sheetwash, slow continuous downslope creep, or a variable combination of these processes.

- Alluvial Deposits Alluvium refers to tin minerals concentraed by the movement of water in a stream or river

Deposits in oceanic submerged river channels are important sources of tin. More than half of the world's tin production is from deposits such as these, mainly in Malaysia, Indonesia and Thailand.

Associated metals

Although most tin is obtained from mining tin ores, cassiterite is also

found in association with ores of tungsten, tantalum and lead and minor

quantities of tin are recovered as by-products of mining these metals.Minerals found with tin:

- tourmaline,

- topaz,

- fluorite,

- apatite,

- wolframite,

- molybdenite,

- and arsenopyrite

Mining

The main method of mining large placer tin deposits is by bucket-line dredging.The alluvium containing the tin is excavated and transported by a continuous chain of buckets to the interior of the dredge where it is washed and roughly concentrated. In South-East Asia particularly, smaller deposits, or those unsuitable for dredging (e.g. because the bedrock is very rough) are worked by gravel pumping.

The alluvium is broken up by a high pressure jet of water and the resulting slurry is pumped to the concentrating plant.

The impure cassiterite concentrate is further concentrated by gravity methods which involve passing the concentrate in a stream of water over equipment such as jigs, spirals, or shaking tables.

This separates the heavy cassiterite from the lighter minerals such as quartz.

Magnetic or electrostatic separation removes the heavy mineral impurities.

The end product is a cassiterite concentrate containing about 70% tin.

Vein and disseminated tin deposits are mined by the same methods used in hard-rock mining of other non-ferrous ores such as zinc.

The ore is broken by drilling and blasting, transported to a concentrator where it is crushed and ground and then concentrated by gravity methods.

The concentrate is usually of a lower grade (about 50% tin) than placer concentrate because of the fine grain size of the cassiterite and the difficulty of removing all the associated sulphide minerals.

Although flotation is not as efficient for tin ores as it is for sulphide ores, it is used increasingly to improve the amount of tin recovered and to recover tin from the residues of earlier treatment.

Australia

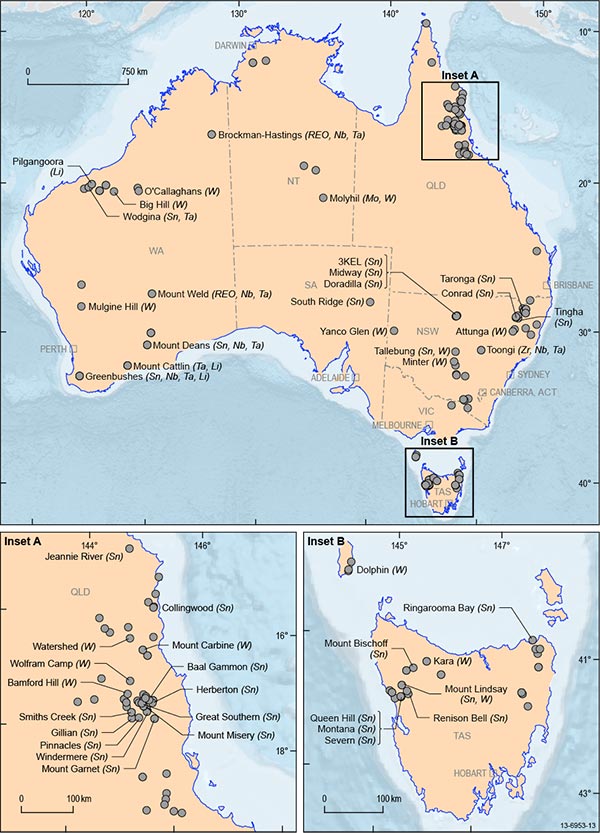

More than 85% of Australia's economic tin resources are located at the

Renison Bell deposit in Tasmania, a primary carbonate replacement deposit

which supports one of the world's largest underground tin mines. Australia's next most important mine is at Greenbushes in Western Australia, where tin is recovered along with tantalite (a tantalum mineral) from a weathered primary deposit.

Other areas where tin production has been important include Ardlethan and Cleveland, which are no longer operating. Gibsonvale, Moolyella, Mount Bischoff, the Herberton/Mount Garnet and Emmaville districts have also been important producers of tin and remain prospective areas. Areas with minor production and/or possible important future sources of tin include Collingwood, Doradilla and the Bynoe Harbour district.

Tin has been mined in the Herberton area of Far North Queensland since 1888. Hard rock tin, associated with greisen on the top of granitic intrusions and alluvial placer tin are mined with associated tungsten and taltalum minerals.

Bolivia

Bolivia has been a significant producer for some years and many of its

mines have been producing for over 50 years. Tin deposits are mostly

complex vein systems where the cassiterite is inter-mixed with sulphides

of silver, bismuth and tin. Over 95 percent of tin production is derived

from hard rock deposits, almost all of which is exploited by underground

exploration.All of the major tin mines are located in the Andean Cordillera of western Bolivia. Most of the mines are situated at heights of between 3,500 and 4,800 metres above sea level on the high plateau area known as the Altiplano. These mines are high cost producers and the quality of the ore grade produced has been declining for some years. Bolivia has been overtaken in recent years by Brazil as a major supplier of tin.

Brazil

In 1990 Brazil was the world's largest producer of tin-in-ore. Almost 90%

of the country's production is obtained from the Pitinga mine about 300 km

northeast of Manaus in the Mapuere region of the state of Amazonas. The

high grade alluvial deposits at Pitinga were discovered at the end of the

1970s in the course of a five-year exploration programme. These deposits

are shallow with a maximum working depth for dredging of six metres.

Simultaneous excavation and suction dredging is capable of mining very low

grades of tin, thus greatly increasing the economic ore reserves. Low

mining costs have allowed production to remain profitable even when tin

prices have been low as in the last few years.

Thailand

The modern commercial production of tin in Thailand began in about 1870,

but it was not until the early part of the 20th century that the country

became a significant producer. Most of the tin produced in Thailand has

been produced in the southern provinces in the Malay Peninsula. The major

ore reserves are cassiterite but substantial quantities of columbite and

tantalite also occur. Thailand was the first country to employ the dredge for offshore tin mining in 1907 and onshore and offshore dredging still accounts for about 27 percent of total production, by the late 1980s. Gravel pump mining became much more important during the 1950s and 1960s as new power-driven machinery replaced the older inefficient recovery systems.

Malaysia

Malaysia's principal tin deposits occur in a strip of land about 400 km

long and 60 km wide between the towns of Georgetown and Melaka, along the

western coast of Peninsular Malaysia. Most Malaysian tin comes from two

states, Perak and Selangor, which together account for about 90 percent of

the country's tin mining output; tin has been produced in Malaysia for

more than 2,000 years. The principal methods of mining are by gravel pump and dredging which account for about 80 percent of total mine output. However during the 1980s there was a substantial fall in the number of gravel pump producers, as it became uneconomic to produce tin in such small mining units in view of the low world price.

Indonesia

Indonesia produces tin mainly from alluvial deposits and the country's

major reserves are located in the offshore areas of Bangka Island.

Commercial exploitation of tin resources began on Bangka Island in the

eighteenth century, but the introduction of large scale dredging

operations in the early part of this century established Indonesia as a

major efficient low cost producer.

China

China is also one of the major tin-producing countries; the main producing

area is the Gejiu complex in Yunnan which has accounted for a large

proportion of the total output in China for many years. Total mined

production of tin in 1990 (as ores and concentrates) was 211,000 tonnes,

with the major producing nations being Brazil, China, Indonesia, Malaysia,

Bolivia and Thailand.

England - Cornish tin

Cornwall has a long history as a leading producer. Cornish tin deposits

have been worked extensively for many centuries, dating back to at least

Roman times; there is in fact strong evidence of tin working in Cornwall

from the early Bronze Age, 2100-1500BC.Even after the Romans reached Cornwall however, tin must have been scarce and costly. There are actually few historical references to the tin trade of the Phoenicians, Greeks, Gauls or Romans. Brief statements about production were made from time to time after 1066 in Stannary Court Proceedings, charters and other official documents.

Tin mining was undoubtedly the most important of the various non-agricultural economic activities in Cornwall in the middle ages and it was part of a highly diversified economic structure. Many Cornishmen were engaged in overseas trade and shipping as well as agriculture during this period.

Cornwall seems to have been one of the world's leading sources of tin for much of its known history, and certainly until the late 19th century. However, output has fluctuated markedly with the economic fortunes of the region. In the 14th century, output reached an annual peak of 600 tonnes.

By the middle of the 19th century Cornwall reached its peak production of about 9,000 tonnes, but by the early 1890s production had fallen to between 4,000 to 5,000 tonnes per year. Output fell further in the first half of this century when the low-cost alluvial resources in South-East Asia became the world's principal source of tin.

Production fell to a low point of 1,000 tonnes per annum in the 1950s but recovered to over 5,000 tonnes per annum in 1984 and 1985, due to the higher world market price. However, following the collapse of world tin prices in late 1985, Cornish mines were gradually closed down and now (1997) the last mine operating at South Crofty, producing around 1,100 tonnes of tin-in-concentrate, is threatened with closure. The largest operating mine currently in Europe is the Neves-Corvo complex in Portugal where both tin and copper are extracted.