Lithium Deposits Australia

Lithium Deposits Australia

Lithium (Li) is a highly reactive alkali metal that offers excellent heat and electrical conductivity. These properties make it particularly useful for the manufacture of glass, high-temperature lubricants, chemicals, pharmaceuticals, and lithium ion batteries for electric cars and consumer electronics. However, because of its high reactivity, pure elemental lithium is not found in nature but is instead present as a constituent of salts or other compounds. Most commercial lithium is available in the form of lithium carbonate, which is a comparatively stable compound that can be easily converted to other salts or chemicals.

There are two major methods of lithium extraction… Conventional Lithium Brine extraction and Hard rock / spodumene LiAl(SiO3)2 lithium extraction

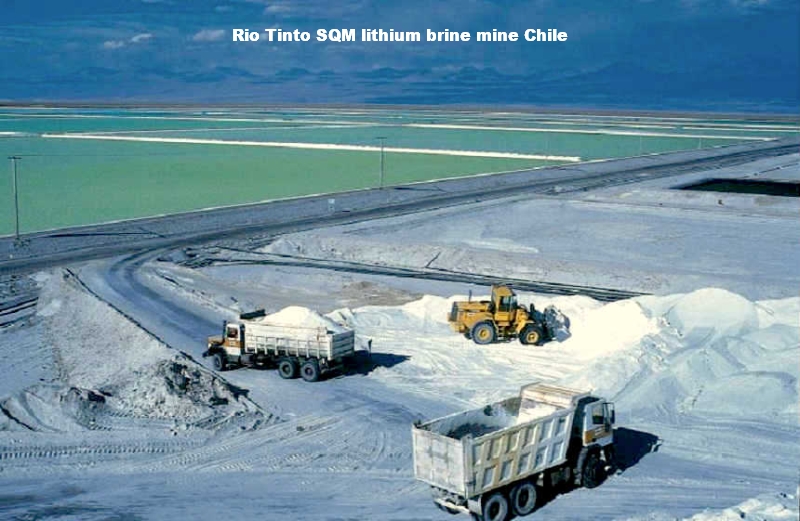

Lithium Brine Extraction

Hard

rock / Spodumene LiAl(SiO3)2 lithium extraction

Other lithium

extraction processes

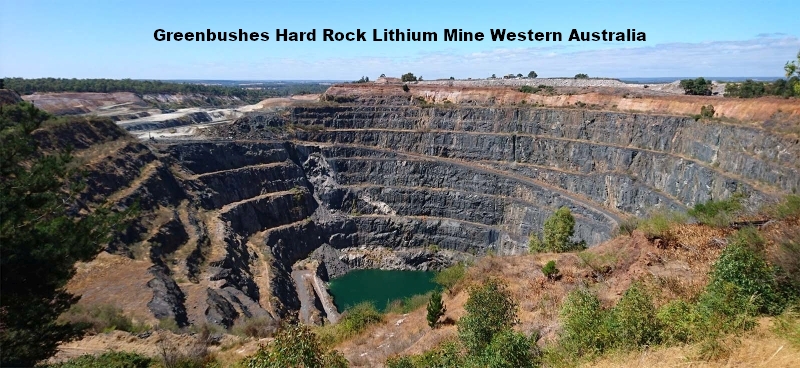

Greenbushes,

Australia - Hard Rock Lithium Mine

Production

of battery grade Lithium Carbonate (Li2CO3) from Spodumene

Making Lithium Metal

Sources

Lithium Brine Extraction

These brines contain lithium derived mainly from the leaching of volcanic rocks and vary greatly in lithium content, largely as a result of the extent to which they have been subject to solar evaporation.

- Highly concentrated lithium deposits in the high altitude salt-flats

known as “salars: found in of Chile, Argentina, Bolivia, Tibet and

China where lithium concentrations can be very high;

- Mid-level brines like Silver Peak, Nevada and Searles Lake,

California (a former location of lithium production);

- Lower concentration brines like the Great Salt Lake, Utah. The lower

concentration brines have modest evaporation rates and dilution is

constant due to a large volume of fresh water inflow and small lithium

concentrations varying between 30 to 60 ppm.

The effectiveness of producing lithium carbonate from salt brines is so favourable that most hard rock mining operations have been priced out of the market with the exception of Australias Greenbushes pegmatite. Lithium brines are currently the only lithium source that can support mining without significant other credits from tantalum, niobium, tin etc.

Once the lithium is recovered by-products include saleable compounds such as potash or boron and the chemicals used can be recycled. Lithium recovery from brines may lead to a significant carbon footprint reduction because of a nearly zero-waste mining method.

Lithium brine recovery is typically a straightforward but lengthy process that can take anywhere from several months to a few years to complete.

- drilling/ digging may be required to access the underground salar

brine deposits, and

- the brine is then pumped to the surface and distributed to

evaporation ponds

- the brine remains in the evaporation pond for a period of months or

years until most of the liquid water content has been removed through

solar evaporation.

- salar brines are very concentrated and, in addition to lithium,

typically contain potassium and sodium

- potassium may be extracted from younger ponds while waiting for the

lithium content to reach a concentration optimal for further

processing

- the brine is pumped to a lithium recovery facility for extraction.

This process varies depending upon the brine field composition, but

usually entails the following steps:

- Pretreatment -This step usually employs filtration and/or ion

exchange (IX) purification to remove any contaminants or unwanted

constituents from the brine.

- Chemical treatment - Next, a series of chemical solvents and

reagents may be applied to isolate desirable products and

byproducts through precipitation.

- Filtration - The brine is then filtered to separate out

precipitated solids.

- Saleable lithium production - The brine is finally treated with

a reagent, such as sodium carbonate to form lithium carbonate, and

the product is then filtered and dried for sale. Depending upon

the desired product, different reagents may be applied to produce

other commonly sold forms of lithium, such as lithium hydroxide,

lithium chloride, lithium bromide, and butyl lithium.

Hard rock / Spodumene LiAl(SiO3)2 lithium extraction

Over 100 different minerals contain some amount of lithium, however, only five are actively mined for lithium production. These include spodumene LiAl(SiO3)2 which is the most common by far, as well as lepidolite (a purplish form of mica), petalite, amblygonite, and eucryptite. Spodumene is a pyroxene mineral consisting of lithium aluminum inosilicate.The process for recovering lithium from ore can vary based on the specific mineral deposit in question. In general, the process entails removing the mineral material from the earth then heating and pulverising it. The crushed mineral powder is combined with chemical reactants, such as sulphuric acid, then the slurry is heated, filtered, and concentrated through an evaporation process to form saleable lithium carbonate, while the resulting wastewater is treated for reuse or disposal.

Other lithium extraction processes

Beyond salar brine and mineral ore, lithium can be produced from a few other sources, though such production is not widespread at this time. These other lithium sources include:

- Hectorite clay. Extensive research and development has been invested

into developing effective clay processing techniques, including acid,

alkaline, chloride and sulfate leaching, as well as water

disaggregation and hydrothermal treatment. To date, none of these

technologies has proven economically viable for extracting lithium

from clay.

- Seawater. Hundreds of billions of tons of lithium is estimated to

exist in our oceans, making them an attractive source for meeting

future lithium demand. While existing processes—including a

co-precipitation extraction process and a hybrid IX-sorption

process—have succeeded in extracting lithium from seawater,

- Recycled brines from energy plants. Efforts to retrieve lithium from

geothermal brines are gaining popularity as worldwide demand for

lithium increases and as new technologies emerge. The processes used

follow conventional brine extraction, though they might be adapted

based on the content of the brine stream.

- Recovered oil field brine. Retrieval of lithium from oil field

brines is technically just another form of conventional brine

extraction, with the difference being the source of the brine.

- Recycled electronics. Lithium battery recycling doesn’t truly meet

the definition of extraction, however, as demand grows, lithium ion

battery recycling will become an increasingly valuable source of the

metal. Currently recycling rates are very low at 20%

Greenbushes, Australia - Hard Rock Lithium Mine

Tin was discovered at Greenbushes in 1886 and by 1890 tantalite was being mined from alluvial ore. Dredges were used to mine placer deposits in the 1960s and ’70s, after which the focus became open-pit mining of weathered pegmatites. With fluctuations in the tantalum markets, currently only lithium minerals are mined from the open pits.

The Greenbushes pegmatite is a giant pegmatite dike of Archean age with substantial Li-Sn-Ta mineralisation, including half the world’s tantalum resource.

This pegmatite swarm was intruded close to, and aligned with, the north to north-northeasterly-trending Donnybrook-Bridgetown shear zone, a regional lineament about 150 km long in the Archean Balingup Metamorphic Belt. The pegmatites at Greenbushes are uncharacteristically fine-grained and sheared due to the association with the Donnybrook-Bridgetown shear zone.

Most permatites contain large mineral crystals but in the case of Greenbushes the crystals are somewhat smaller. Its mineral reserve is very unique grading 50% spodumene LiAl(SiO3)2 This makes Greenbushes the highest grade lithium mineral resource in the world at 3.9% Li2O mineral reserves and 3.5% Li2O mineral resources versus 1.0 - 2.0% Li2O for other known hard rock deposits.

This highly prospective structural lineament continues for 50km and is characterised by deformed gneiss, orthogneiss and migmatites.

Australia supplies roughly a third of the world's lithium demand and 75% of Chinese demand. This gives Australia potentially considerable leverage against Chinese and other imposed trade sanctions if there is a political will.

The Greenbushes Lithium Operation has been producing lithium for over 25 years. The mine is located 250 kilometers (km) south of Perth/Fremantle - a major container shipping port - and 90 km south east of the Port of Bunbury, a major bulk handling port in Western Australia.

The Greenbushes ore body is a highly mineralized zoned pegmatite with a strike length of more.than 3 km.

Talison's Greenbushes lithium mineral resource is open along strike and at depth so there is significant potential to increase lithium mineral reserves and mineral resources extending the life of mine while at the same time increasing production rates.

Talison's Greenbushes Lithium Operation produces two categories of lithium concentrates:

- technical-grade lithium concentrates - low iron content for use in

the manufacture of glass, ceramics and heat-proof cookware; and

- high yielding chemical-grade lithium concentrate - used to produce

lithium chemicals which form the basis for manufacture lithium-ion

batteries for laptop computers, mobile phones and electric cars.

Production of battery grade Lithium Carbonate (Li2CO3) from Spodumene

Spodumene (LiAl(SiO3)2 ) is a pyroxene mineral consisting of lithium aluminum inosilicate. It occurs as colorless to yellowish, purplish, or lilac kunzite, yellowish-green or emerald-green hiddenite, prismatic crystals, often of great size. Concentrates suitable for lithium carbonate production contain 75-87% spodumene. The typical impurities in spodumene concentrates are quartz (SiO2), alumina (Al2O3), and biotite, a solid solution of annite (KFe3AlSi3O10(OH)2) and phlogopite (KMg3AlSi3O10(OH)2).

Under typical (low) temperatures, spodumene is in the α-spodumene form, which exhibits low reactivity due to its monoclinic structure. Above 800-900°C α-spodumene transforms into β-spodumene, which exhibits tetragonal structure, thus larger cell volume and Li+-H+ cation exchange properties. The β-spodumene obtained at temperatures above 900 °C is therefore reactive and suitable for metallurgical . A brief outline of the process...

treatment.

- Decrepitation and Sulfation – heated to 1070 degrees celsius to

convert to β-spodumene, cooled and reacted with sulphuric acid to

convert to a lithium sulphate

- Neutralisation and Leaching – the lithium sulphate is neutralised

with calcium hydroxide and the solids dewatered and washed (the

liquids - still containing lithium sulphate are recycled), an acid

neutralisation pH 5-6 removes iron and aluminium and a neutralisation

pH 10-11 removes magnesium – the filtrate now contains mostly

dissolvedl ithium sulphate and is reacted with sodium carbonate which

converts 98% to lithium carbonate Li2CO3

- Purification – involves cooling and crystallisation of dissolved

lithium carbonate followed by washing nin a rotary vacuum filter

Making Lithium Metal

Converting lithium into metal is done in an electrolytic cell using lithium chloride. The lithium chloride is mixed with potassium chloride in a ratio of 55% to 45% in order to produce a molten eutectic electrolyte. Potassium chloride is added to increase the conductivity of the lithium while lowering the fusion temperature.

When fused and electrolysed at about 449 degrees celsius, chlorine gas is liberated while molten lithium rises to the surface, collecting in cast-iron enclosures. The pure lithium produced is wrapped in paraffin wax to prevent oxidization. The conversion ratio of lithium carbonate to lithium metal is about 5.3 to 1.

Australia is sunny and windy and we should be energy independent and save the huge cost of imposed involvement in global energy related conflicts.

The energy is free and cheap, yet we appear to do little to value add by producing / exporting solar and wind generating equipment.

Abundant renewable electrical energy can easily be collected during the day. But peak demand for electricity is early evening and most charging of electric vehicles will take place overnight. Lithium battery storage could meet this electrical storage need.

Sources:

http://www.lithiummine.com/lithium-mining

https://www.researchgate.net/publication/340593032_Lithium_Extraction_from_Spodumene_Ore_-_Techno-Economic_Assessment_with_SuperPro_Designer

https://www.thoughtco.com/lithium-production-2340123

https://www.samcotech.com/what-is-lithium-extraction-and-how-does-it-work/

https://en.wikipedia.org/wiki/Greenbushes_mine

https://lithium-au.com/greenbushes/

Images

https://www.mindat.org/photo-692820.html

http://www.mining.com/rio-tinto-race-stake-worlds-largest-lithium-miner/