Gold Placer Deposits

Gold Placer Deposits

Where to Find Placers

Problems With Water

Basic EquipmentSupplies

Panning for Gold

Evaluation: Should You Invest And Mine?

Sampling Techniques

Calculating What You Might Have

How To Go About Mining

Choosing a Recovery Method

Gold Pan

Rocker

Dip-Box

Long Tom

Sluice

Dry Washer (for Desert Areas)

Surf Washer (for Beach Deposits)

Skindiving (Combining Recreation)

Problems You Should Anticipate In Placer

Mining

Palmer River Goldfield

Where to Find Placers

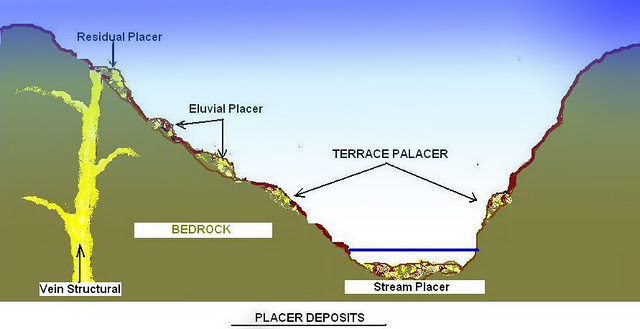

Placers can be found in virtually any area where gold occurs in hard rock (lode) deposits. The gold is released by weathering and stream or glacier action, carried by gravity and hydraulic action to some favorable point of deposition, and concentrated in the process. Usually the gold does not travel very far from the source, so knowledge of the location of the lode deposits is useful. Gold also can be associated with copper and may form placers in the vicinity of copper deposits, although this occurs less frequently.Geological events such as uplift and subsidence may cause prolonged and repeated cycles of erosion and concentration, and where these processes have taken placer deposits may be enriched. Ancient river channels and certain river bench deposits are examples of gold-bearing gravels that have been subjected to a number of such events, followed by at least partial concealment by other deposits, including volcanic materials. Residual placer deposits formed in the immediate vicinity of source rocks are usually not the most productive, although exceptions occur where veins supplying the gold were unusually rich. Reworking of gold-bearing materials by stream action leads to the concentrations necessary for exploitation. In desert areas deposits may result from sudden flooding and outwash of intermittent streams.

As material gradually washes off the slopes and into streams, it becomes sorted or stratified, and gold concentrates in so-called pay streaks with other heavy minerals, among which magnetite (black, heavy, and magnetic) is almost invariably present. The gold may not be entirely liberated from the original rock but may still have the white-to-gray vein quartz or other rock material attached to or enclosing it. As gold moves downstream, it is gradually freed from the accompanying rock and flattened by the incessant pounding of gravel. Eventually it will become flakes and tiny particles as the flattened pieces break up.

Some gold is not readily distinguishable by the normal qualities of orange-yellow to light yellow metallic color and high malleability, where it occurs in a combined form with another element, such as tellurium. Upon weathering, such gold may be coated with a crust, such as iron oxide, and have a rusty appearance. This "rusty gold," which resists amalgamation with mercury, may be overlooked or lost by careless handling in placer operations.

As mentioned before, the richest placers are not necessarily those occurring close to the source.Much depends on how the placer materials were reworked by natural forces. Streambed placers are the most important kind of deposit for the small-scale operator, but the gravel terraces and benches above the streams and the ancient river channels (often concealed by later deposits) are potential sources of gold. Other types of placers include those in outwash areas of streams where they enter other streams or lakes, those at the foot of mountainous areas or in regions where streams enter into broader valleys, or those along the ocean front where beach deposits may form by the sorting action of waves and tidal currents. In desert areas, placers may be present along arroyos or gulches, or in outwash fans or cones below narrow canyons.

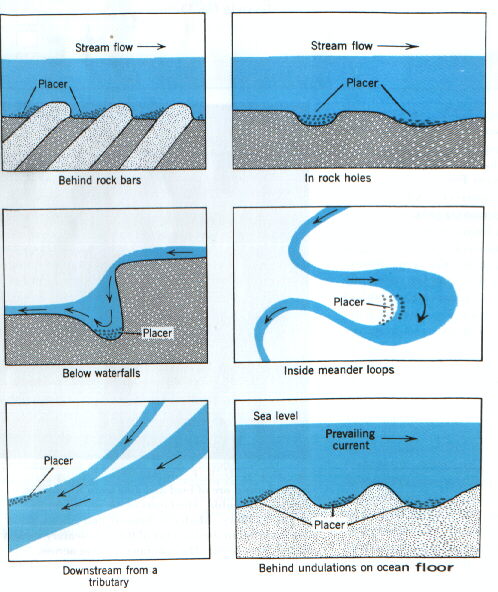

Because gold is relatively heavy, it tends to be found close to bedrock, unless intercepted by layers of clay or compacted silts, and it often works its way into cracks in the bedrock itself. Where the surface of the bedrock is highly irregular, the distribution of gold will be spotty, but a natural rifflelike surface favors accumulation. Gold will collect at the head or foot of a stream bar or on curves of streams where the current is slowed or where the stream gradient is reduced. Pockets behind boulders or other obstructions and even moss-covered sections of banks can be places of deposition. Best results usually come from materials taken just above bedrock. The black sands that accumulate with gold are an excellent indicator of where to look.

It should be kept in mind that each year a certain amount of gold is washed down and redeposited during the spring runoffs, so it can be productive to rework some deposits periodically. This applies chiefly to the near-surface materials such as those deposited on the stream bars or in sharp depressions in the channels. The upstream ends of stream bars are particularly good places for such deposits. Where high water has washed across the surface by the shortest route, as across the inside of a bend, enrichment often occurs.

A rifflelike surface here will enhance the possibility of gold concentration. In prospecting areas with a history of mining, try to find places where mechanized mining had to stop because of an inability to follow and mine erratic portions of rich pay streaks without great dilution from nonpaying material. Smaller scale selective mining may still be practical here if a miner is diligent.

Problems With Water

The need for a good, dependable, and plentiful supply of water increases geometrically with the scale of operation in placer mining. Panning gold requires very little water and can be done in a small tub if necessary. At the other extreme, the hydraulic monitor, once in use, employed large flows of water under high pressure, and sluicing at a large operation could consume virtually all the water that might be available. One thing the placer miner must keep in mind is the seasonal nature of stream flow. This affects both the supply of water and also the problems of pollution for downstream users and damage to stream ecology.Various means are used to divert and impound water. Channels, pipes, and flumes can beconstructed to conduct water where it is wanted. If supply at a continuous flow is limited, storage must be provided, and placer operation is then restricted to periodic activity and depends on the capacity of the reservoir. A simple tank may make a suitable reservoir for a small operation. Pumps are commonly used now where power is cheap enough, and the recirculation enables use of a smaller supply of water.

Basic Equipment

Among the essential implements needed for prospecting are a pick; a long-handled, round-pointed shovel; and a gold pan, preferably a 30-40cm diameter pan which can usually be purchased at hardware stores in gold-mining areas. A small prospector's pick is also useful, and a magnet and a small amount of mercury should be carried to separate the gold from black sand after panning.Specialty stores and manufacturers can provide the more elaborate equipment, such as skindiving gear, ready-built sluices, and mechanical gold separation devices, if desired.In some cases, a bucket or wheelbarrow may be needed to transport materials to the washing site, and in addition, a heavy .25-.75cm -mesh screen is handy to separate out coarse materials. A small screen cut to nest in the upper part of a gold pan can be useful for the same purpose in panning. A gold pan the same size as the one used for panning will make a most efficient nesting screen if a close pattern of holes is drilled in the bottom. Holes usually should be .24-.75cm in diameter, depending on the average size of the material being sampled. Distance between holes should be about the same as the diameter of the holes. In some areas these pans can be purchased readymade. For weighing gold, a small balance scale graduated in milligrams may be desirable. A compact, folding type of balance is available for this purpose.

A compass will be needed for establishing claim lines and for finding your way out of the woods if lost. Adequate maps should be carried. A hand magnifying lens is helpful in identifying minerals. Bags may be needed to carry out samples; plastic bags are the best because samples may be damp. A rocker may be transported to the site either assembled or in a knocked-down condition. If mining is planned, lumber and other materials to build a sluice may be carried to the site. (See construction details under respective headings.) More elaborate equipment such as pumps, pipes, hoses, and light plants might be taken in by pack animals if desired.

Personal gear includes a good pair of boots, sturdy clothing, weatherproof gear, sleeping bag, tent, and such other things as one might want for comfort and sanitation. A foam pad or air mattress adds comfort to sleeping. A length of rope is useful for many purposes around camp, from raising the food out of reach of animals to extracting a car from a mudhole. For hiking, all necessary equipment for the period away from camp should fit into a manageable backpack of some kind.

An ax, a flashlight, a knife, and matches are almost indispensable. A water bucket is often required, and a good crosscut saw will be found useful. Guns and fishing equipment can be taken to supplement the food supply and to provide some additional recreation. Guns are seldom necessary for protection from animals. A canteen with a 2-quart or larger capacity is advisable in many areas, depending on dryness of the climate. You will need water-purification tablets where streams are contaminated, whether by grazing stock or for other reasons. A miner's lamp, which consumes calcium carbide, is sold at some hardware stores and can be used for a serviceable light, although most people when away from electricity prefer gasoline or propane lamps. A carbide lamp will also be useful for any underground work. The special miner's safety lamp is recommended wherever air may be bad. Stoves that burn gasoline or pressurized gas are in wide use in camping and even gas refrigerators may be taken along "to cool the beer." (For low-budget operations, a swift-running stream will serve this same purpose well.) For any length of time in the field, an oven for baking is a valuable amenity. A reflector oven for use next to a campfire can be made of light sheet metal and will give excellent results, also serving as a place to keep food warm.

Supplies

Freeze-dried foods are generally good and easy to carry and prepare, although somewhat more expensive than most other foods. For estimating pack weights, about 2 pounds of dehydrated and freeze-dried foods is needed per person per day. Canned foods should be avoided when backpacking because of their weight, but they are otherwise satisfactory. Disposal of empty containers should be done with consideration to others who may follow and wish an uncluttered landscape; burial is usually recommended.Suggested food supplies for a prospector's camp include the following: bacon, beans, cheese, salt, baking powder and soda, coffee, tea, onions, potatoes, fruits, corn. peas. raisins, rice, flour, crackers, cereals, butter or margarine, powdered milk, eggs, pancake and waffle mix, sugar, syrup, and fresh meat and vegetables as practicable. Many other items can be added to the list, but these are most of the basics. Utensils should include a variety of dishes, silverware, a sharp knife, spatula, can opener, frying pan, coffee pot, and several different sizes of pots and pans. Towels, both paper and cloth, soap, scouring pads, and metal or plastic tubs or basins will be needed for cleaning up.

Extra clothing should be included in your supplies for warmth and for changes. Mosquito netting may be a virtual necessity in some areas, and adequate amounts of a good insect repellent should be packed.

Wild animals are seldom dangerous except when provoked, but smaller ones such as packrats can inflict considerable damage on camp gear and foodstuffs. Poisonous snakes, spiders, ticks, scorpions, and the like should be treated with traditional caution; their presence should be anticipated in most areas. Learn to identify and avoid poison oak and poison ivy' Knowledge of first aid is essential for dealing with emergencies that might arise on an outing, and a study or review of the subject should be included in any preparations.

Some of the personal hazards faced in the out-of-doors include twisted ankles, lacerations from falling in brush, falls from slippery rocks or crude bridges when crossing streams, breaking through floors in old building ruins, and falls or cave-ins in old mine workings. Beware of bad air in any old workings' Danger of drowning or being attacked by a crocodile is always present when working around the deeper streams or pools when placer mining.

Many types of first aid kits and equipment are on the market. The choice of kit is one of size and variety of content. A snakebite kit is usually a separate accessory and should be carried, even though it is rarely put to use. Disinfectants, aspirin, fungicides, bandages, and similar items should be included. For areas of considerable sunshine, tanning lotion, sunglasses, and a hat are needed, and salt tablets should be taken as designated to prevent heat prostration. Wearing a safety hardhat and safety glasses may be advisable at times.

Panning for Gold

The standard gold pan is made of stiff sheet iron and is 35cmin diameter at the top and 5-6cm deep. The rim is flared outward at an angle of about 50 degrees from the vertical. Smaller pans are used for testing, and it is advisable for most panners to use either a 30-40cm size for handling ease. Probably the 1.25cm is the most widely available. Frying pans or other cooking utensils may also be used for washing out gold but are less effective. Before any kind of container is used for panning it should be cleaned thoroughly and all grease should be burned out. New pans generally are greasy and should be heated over a fire until this coating is gone. Even a rusty pan, if clean, can be used satisfactorily. In fact, the roughness due to the pitting of the rust may assist in holding back the gold.

There are different techniques and subtle variations in the art of panning--experience teaches which is best. Those with wide experience and much practice can recover the most gold with the least effort.It is sometimes said that good panning technique lies in the action of the wrists. After much practice the good panner should be able to save even the very fine gold that may be nearly but not quite free from the black sands.

The pan usually is filled level with the top, or slightly rounded, depending somewhat upon the nature of the material being washed and the personal preference of the panner. It is then submerged in water. Still water 20-30cm deep is best. While under water the contents of the pan are kneaded with both hands until all clay is dispersed and the lumps of dirt are thoroughly broken. The stones and pebbles are picked out after the fines are washed off. Then the pan is held flat and shaken under water to permit the gold to settle to the bottom. The pan is then tilted and raised quickly -- still under water -- so that a swirling motion is imparted and some of the lighter topmaterial is washed off. This operation is repeated, occasionally shaking the pan under water or with water in it until only the gold and heavy minerals are left. With proper manipulation, this material concentrates at the edge of the bottom of the pan. Care must be taken that none of the gold climbs to the lip of the pan or gets on top of the dirt.

Nuggets and coarse colors of gold can now be picked out readily with a tweezer or with the point of a knife. Cleaning the black sand from the finer gold is more difficult, but can be carried nearly or entirely to completion by careful swirling of the contents as described above, always watching to see that none of the colors are climbing toward the lip. This part of the operation usually is done over another pan or in a tub so that if any gold is lost it can be recovered by repanning.

The concentrates should be dried, and the black sands (composed largely of magnetite) can then be removed by a magnet or by gently blowing them on a smooth flat surface. If there is an excessive quantity of black sand, the gold usually is amalgamated by putting a portion of a teaspoonful of mercury in the pan. In sampling work, extra care should be taken to see that no fine colors are lost. When mining, however, additional time needed to insure that all colors are saved probably is not justified because the value they add is so small.

A word should be said here about other minerals that you may see in your gold pan. Pyrite ("fool's gold," an iron sulfide) and mica are often mistaken for gold by the novice. Pyrite, which is usually a brassy yellow to white color, will shatter when struck with a hammer and becomes a black powder when finely ground. Mica, which may have a bright, bronzy appearance, is distinguished by its light weight and flat, platy cleavage. Both minerals are common in gold areas. Other minerals that will collect with the gold and black sands because of high specific gravity include ilmenite (iron-titanium oxide), hematite (nonmagnetic iron oxide), marcasite (an iron sulfide), rutile (titanium oxide), scheelite (calcium tungstate), wolframite (iron, manganese tungstate), tourmaline (boron and aluminum silicate), zircon (zirconium silicate), chromite (iron and chromium oxides), and cinnabar (mercury sulfide). If present in sufficient quantity, these latter minerals may have some economic significance, although efforts to recover them as byproducts are seldom worthwhile.

Native platinum, elemental mercury, lead shot, and similar materials are also occasionally found in the pan.

Evaluation: Should You Invest And Mine?

This question becomes more difficult to answer as the size of the planned operation increases.Estimation of the amount of gold recoverable and the overall costs of investment and mining is no simple matter and calls for highly experienced engineering skills for any moderate- to large-scale project. Elaborate procedures of sampling and evaluation cannot be followed by the small-scale operator because of the cost. Thus, his decisions must be based on a variety of factors, not the least of which is intuition. Needless to say, many mistakes have been made, with much resultant waste of money and effort. Do not let what started out as a recreational activity become your master instead of your servant.Sampling Techniques

Many methods of sampling are possible, including the simple panning of gravel from surface exposures, churn drilling, test pitting and trenching, shaft sinking, and drifting. As an aid in tracing possible gold-bearing channels, geophysical techniques have been employed with some success, but proper use of the typical instruments involved is generally reserved to experts. Moreover, interpretation of results is seldom adequate to provide any quantitative estimates, although the information gained can be useful in planning an exploration program.Panning and rocking (described later) are the basic means of determining the recoverable gold content of placer materials. A fire assay, sometimes made on a concentrate, provides a relatively complete estimate of the gold content of the material, but a poor estimate of how much gold can actually be extracted by conventional washing methods.

Thus, placer gold is seldom assayed, exceptto determine its fineness (measure of gold purity). In estimating the value of gold in the pan after washing a quantity of gravel, the technique of counting nuggets and "colors" is normally followed. Generally, pieces worth more than 50 or 100 cents are considered as nuggets; smaller particles are colors. When skill is developed in estimating the various sizes of particles, a good degree of consistency can be achieved in the results.

Where samples can be obtained across a section of the bank exposed along a creek, it is good practice to cut a vertical groove or channel of fairly consistent width and depth. The sample may be cut from top to bottom, or in segments comprising several different samples if the bank shows distinct changes in materials. Bars may be sampled by digging a vertical hole, clear to bedrock if possible, and panning the product. For surface mining of "skim bars," sampling consists of simply taking a panful from a favorable point and visually estimating the amount of similar material in the vicinity. Clearly, there is not much accuracy in any of these methods, but the deposition of gold in such locations is bound to be erratic anyway. More representative sampling is usually possible in the larger deposits where deposition and size of gold particles is more uniform or consistent.

Calculating What You Might Have

For the small-scale miner, sampling will usually be limited to taking a panful here and there and possibly running a larger sample through a rocker or sluice if panning discloses any gold. If colors are found, a record should be made of the number and estimated size of colors per pan and the approximate location. The sampling then progresses until one is assured the prospects are good enough to warrant a mining operation of some sort. A scale of sizes and approximate values of colors based on pure gold at $350 an ounce is as follows:(Note: Mesh = screen size in openings per square inch; minus 10- plus 20-mesh material will passscreen with 10 openings per square inch but be stopped by screen with 20 openings.)

Coarse gold, plus 10 mesh: should be picked out and weighed individually, value about $10 each

Medium gold, minus 10 mesh but plus 20 mesh: 2,200 colors per troy ounce, value about two-thirds of a color to about 30 cents

Fine gold, minus 20 mesh but plus 40 mesh: 12,000 colors per troy ounce, value about 3 colors to 1 cent. "Flour" gold, minus 40 mesh: 40,000 colors per troy ounce, value about 10 colors to 1 cent. Differing fineness or price will affect the values somewhat.

It is common to report panning results in cents per pan. So, assuming you have determined that a "pan factor" of about 400 pans per cubic metre (bank measure) for the 30cm pan is a suitable figure, multiplying the cents-per-pan figure by 400 gives the estimated value per cubic metre.

Another means of estimating is to rank the colors into three groups, as follows:

Number l: colors weighing over 4 milligrams

Number 2: colors weighing between 1 and 4 milligrams

Number 3: colors weighing less than 1 milligram

(Note: 31,103 milligrams equals 1 troy ounce.)

Scales will be needed to check the weights until the eye can judge the sizes properly. It is recommended that particles over 10 milligrams be weighed individually. A rough measure of value is one-tenth of a cent per milligram.

Thus, the value in a pan can be calculated using your visual count and tally of the number of colors of each rank. After sufficient practice, good estimates will come easily. Thickness has a great bearing on weight: For instance, some gold might look large, but actually be flat, flaky, and hence very light.

Determining the overall value of a deposit with any accuracy calls for a knowledge of accepted practices and mathematical procedures for weighting the values and sample intervals. It is important also to understand the statistical principles of variation and distribution, which are beyond the scope of this report. Generally, the practical prospector will take a few measurements,make some crude calculations using his panning results, and decide to stay or move on.

How To Go About Mining

When a site where gold is known to occur has been found, and after it has been sampled and judged worthy of further effort, the ownership status should be checked to assure that the ground is open for claiming. Then, after staking adequate claims (or arranging to lease if the ground is not open to claim), you are ready to consider mining. Whether mining permits are required should be investigated, because placer operations of any size may drastically change the local water quality. A simple operation may have virtually no effect on a stream or surroundings, but when materials amounting to more than a few cubic metres a day are handled, the possible effects begin to become significant.Choosing a Recovery Method

Among the simpler hand methods of recovering gold are the gold pan, the rocker, the dip-box, thelong tom, and the sluice. Panning has been described in a previous section, entitled "How to Look for Placers," and will only be discussed briefly here. The pan is generally too slow to be effective for anything more than prospecting. The rocker is a time-honored device of the small-scale miner with limited means. The dip-box and long tom might be considered more like simplified sluicing methods than distinct methods in themselves. As a method, the long tom has never been very popular but is described here for its possible historical interest. Other methods used in specific circumstances would include the surf washer, the dry washer, and skindiving.The simpler methods all normally involve hand-mining operations (shoveling and/or picking of the gold-bearing materials). Limited mechanization is sometimes practical for moving and washing gravels in even the smallest operation, and this possibility should not be overlooked. Even motorized devices for panning are marketed by several manufacturers. Pumps and small excavators can often be adapted to the small mining operation by the enterprising miner.

The more complex methods, such as ground sluicing, hydraulicking, drift mining, excavation using powered equipment, and dredging, require considerable investment, knowledge, and experience; a full discussion of these methods is beyond the scope of this report.

The choice of method depends primarily on the scale of operation and the availability of water. These and other characteristics of the different methods are discussed below.

Gold Pan

Panning is the hardest way to wash gold from placer gravels, but it is an inexpensive and completely mobile method. A person can dig with a pick and shovel much faster than he can pan the material dug, so it pays to treat only the highest grade products by panning once one has settled down to mining.An experienced person can wash about 10 large pans per hour, the equivalent of approximately 1/2 to 1 cubic metre of gravel per day, depending on how clean the gravel is. A level-full, standard 30cm pan might contain roughly 22 pounds of dry bank gravel; there are approximately 150 to 180 pans per cubic metre of gravel. More than twice as many 30cm pans would be required per cubic metre. The top dirt or cover is usually cast aside and the few centimteres of material directly above bedrock and the material scraped from crevices is panned. Places to look and the proper panning technique have been covered in earlier sections.

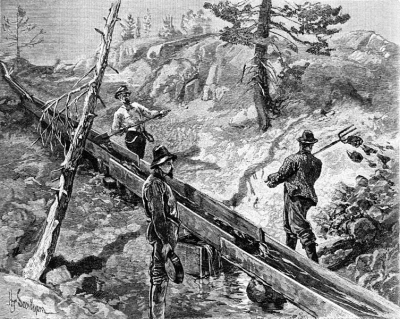

Rocker

At least twice as much gravel can be worked per day with the rocker as with the pan. The rocker or cradle, as it is sometimes called, must be manipulated carefully to prevent loss of fine gold. With the rocker, the manual labor of washing is less strenuous, but whether panning or rocking, the same method is used for excavating the gravel.The rocker, like the pan, is used extensively in small-scale placer work, in sampling, and for washing sluice concentrates and material cleaned by hand from bedrock in other placer operations. One to three cubic metres, bank measure, can be dug and washed in a rocker per man-shift, depending upon the distance the gravel or water has to be carried, the character of the gravel, and the size of the rocker. Rockers are usually homemade and display a variety of designs. A favorite design consists essentially of a combination washing box and screen, a canvas or carpet apron under the screen, a short sluice with two or more riffles, and rockers under the sluice. The bottom of the washing box consists of sheet metal with holes about 1.25cm in diameter punched in it, or a 1.25cm-mesh screen can be used. Dimensions shown are satisfactory but variations are possible. The bottom of the rocker should be made of a single wide, smooth board, which will greatly facilitate cleanups. The materials for building a rocker cost only a few dollars, depending mainly upon the source of lumber.

After being dampened, the gravel is placed in the box, one or two shovelfuls at a time. Water is then poured on the gravel while the rocker is swayed back and forth. The water usually is dipped up in a simple long-handled dipper made by nailing a tin can to the end of a stick. A small stream from a pipe or hose may be used if available. The gravel is washed clean in the box, and the oversize material is inspected for nuggets, then dumped out. The undersize material goes over the apron, where most of the gold is caught. Care should be taken that not too much water is poured on at one time, as some of the gold may be flushed out. The riffles stop any gold that gets over the apron. In regular mining work, the rocker is cleaned up after every 2 to 3 hours, or oftener when rich ground is worked and gold begins to show on the apron or in the riffles. In cleaning up after a run, water is poured through while the washer is gently rocked, and the top surface sand and dirt are washed away.

Then the apron is dumped into a pan. The material back of the riffles in the sluice is taken up by a flat scoop, placed at the head of the sluice, and washed down gently once or twice with clear water. The gold remains behind on the boards, from which it is scraped up and put into the pan with the concentrate from the apron. The few colors left in the sluice will be caught with the next run. The concentrate is cleaned in the pan.

Skillful manipulation of the rocker and a careful cleanup permit recovery of nearly all the gold. Violent rocking should be avoided, so that gold will not splash out of the apron or over the riffles.The sand behind the riffles should be stirred occasionally, if it shows a tendency to pack hard, to prevent loss of gold. If the gravel is very clayey it may be necessary to soak it for some hours in a tub of water before rocking it.

Where water is scarce, two small reservoirs are constructed, one in front and the other to the rear of the rocker. The reservoir at the front serves as a settling basin. The overflow drains back to the one at the rear, and the water is used over again.

The capacity of rockers may be increased by using power drives. Such a device might be rocked by an eccentric arm at the rate of approximately forty 15cm strokes per minute. The capacity of the typical machine with two men working is 1 cubic metre per hour. Where gravel is free from clay, the capacity may be as great as 3 cubic metres per hour. The cost of the mechanized rocker and a secondhand engine for driving it is estimated at $400.

Dip-Box

The dip-box is useful where water is scarce and where an ordinary sluice cannot be used because of the terrain. It is portable and will handle about the same quantity of material as the rocker. Construction is relatively simple. The box has a bottom of 2.5 by 30cm lumber to which are nailed 2.5 by 30 cm sides and an end that serves as the back or head. At the other end is nailed a piece approximately 2.5cm high. The bottom of the box is covered with burlap, canvas, or thin carpet to catch the gold, and over this, beginning 30cm below the back end of the box, is laid a 30 by 90cm strip of heavy wire screen of about 0.5cm mesh. The fabric and screen are held in place by cleats along the sides of the box. Overall length may be 2 to 3 metres, although nearly all gold will probably collect in the first 1metre. The box is placed so the back is about waist high; the other end is 15 to 30 cm lower. Material is simply dumped or shoveled into the upper end and washed by pouring water over it from a dipper, bucket, hose, or pipe until it passes through the box. The water should not be poured so hard that it washes the gold away. Larger stones (after being washed) are thrown out by hand, or a screenbox can be added to separate them. Riffles may be added to the lower section of the box if it is believed gold is being lost.Long Tom

A long tom usually has a greater capacity than a rocker and does not require the labor of rocking. It consists essentially of a short receiving launder, an open washing box 2 to 4 metres long with the lower end a perforated plate or a screen set at an angle, and a short sluice with riffles . The component boxes are set on slopes ranging from 5-7cm per 30cm. The drop between boxes aids in breaking up lumps of clay and freeing the contained gold.

A good supply of running water is required to operate a long tom successfully. The water is introduced into the receiving box with the gravel, and both pass into the washing box.

The sand and water pass through the screen's 1.25cm openings and into the sluice. The oversize material is forked out. The gold is caught by the riffles. The riffle concentrates are removed and cleaned in a pan. Quicksilver may be used in the riffles if the gravel contains much fine gold.

The quantity of gravel that can be treated per day will vary with the nature of the gravel, the water supply, and the number of men employed to shovel stones into the tom and then fork them out. For example, two men, one shoveling into the tom and one working on it, might wash 6 cubic metres of ordinary gravel, or 3 to 4 cubic m of cemented gravel, in 10 hours.

A tom may be operated by four men--two shoveling in, one forking out stones, and one shoveling fine tailings away. Where running water and a grade are available, a simple sluice is generally as effective as the long tom and requires less labor.

Sluice

A sluice is generally defined as an artificial channel through which flows controlled amounts of water. In gold placering, the sluice includes sluiceboxes which collect the gold by means of various configurations of riffles, corrugations, mats, expanded metal, or the like, which trap the heavier particles while allowing the waste to continue through.An important part of any sluicing operation is its water supply, and where water is not plentiful, pumps, pipelines, or even dams with special headgates may be required.

Small-scale sluicing by hand methods has been called quite appropriately shoveling-into-boxes. In contrast, in ground sluicing, usually a more efficient operation, most of the excavation is accomplished by the action of water flowing openly over the materials to be mined. In either case, the materials pass through a sluice, where gold is collected behind riffles. A variation of the sluicing technique, where water is stored and released against or across the materials intermittently, is called booming.

The sluicebox in its simplest form might be a 4m-long plank of 2.5-5cm pine lumber, to which sides about 25-30cm high are nailed, with braces secured at several places across the top. Larger sluices can be made with battens to cover joints between boards where gold might slip out, and with braces built around the outsides of the box for greater rigidity. To provide for a series of boxes, the ends should be beveled or the units tapered so that one will slip into the other in descending order and form a tight joint. Four to eight such boxes in series would be a typical installation. Two men hand-shoveling into sluiceboxes can wash 5 to 10 times as much gravel as could be put through a rocker in a day. The slope of the sluice and the supply of water must be adjusted so that the gravel, including larger cobbles, will keep moving through the boxes and on out. Slopes of 10-15cm per 30cm box are normal, but if water is in short supply the slope may be increased. Trestles are necessary to support the boxes over excavated ground, gulleys, or swales.

Inside the boxes, various kinds of riffles may be employed, depending upon availability of material and personal preference. The riffles, which go on the bottom, are usually set crosswise in the box, but they can also be effective when placed lengthwise, the concentrates settling between them. They may be of wood, or of strap or angle iron, or a combination of the two. Straight, round poles or a pattern of square blocks or stones can serve for riffles. Rubber or plastic strips have even been used. Durability is important for prolonged operations, so wood may be armored with metal. Expanded metal, heavy wire screen, or cocoa mats make good riffles for collecting fine gold.

A common height for riffles is 5-7cm ; they may be placed from one-half to several cm apart. Fastening the riffles to a rack, which is then wedged into place in the box, permits their removal. A tapered shape on the cross riffle, with the thinnest edge to the bottom, tends to create an eddying action that is favorable for concentration. Another way to achieve this eddying action is to cant the riffle or even just the top of the riffle. Burlap or blanket material is commonly placed under the riffles to help in collecting fine gold. Mercury may be added to some sections of the sluice if there is much fine gold, but care must be taken to prevent escape of the mercury.

Sluice cleanups should be made at fairly regular intervals. After running clear water until the sluice is free of gravel, riffles are removed in sections starting at the upper end. With a thin stream of water, the lighter of the remaining material is washed to the sections below. The gold, heavy sands, and amalgam, if mercury has been used, are scraped up and placed in buckets. This mixture then can be panned or cleaned up in a rocker to obtain a final concentrate or amalgam. Feeding the Sluice

It is common in a small operation, when feeding the sluice, to place a heavy screen or closely spaced bars of some sort across the section where the gravels enter, to eliminate the larger particles, which are probably barren anyway. The screen or bars (a "grizzly") should be sloped so the oversize material rolls off to the side. The size of mesh or spacing will depend upon the gradation of feed, butwould generally be in the range of 0.5-2.5cm, with 0.5cm being a common size. In larger operations a rotating screen, or trommel, might be used. In a ground sluicing operation, possibly all materials would be run through the sluiceboxes. Provisions must be made for removing the oversize material, and, if required, stacking it away from the work area.

If the gravel contains much clay it may be desirable to use a puddling box at the head of the string of sluiceboxes. This may be any convenient size--for instance, 1 metre wide by 2 metres long, with 10 to 15cm sides. The clayey material is shoveled into this box and broken up with a hoe or rake before being allowed to pass into the sluice. The importance of this step is that if allowed through the sluice, the unbroken clay lumps may pick up and carry away gold particles already deposited.

Usually, the shoveling-in method proceeds as follows:

- After the boxes are set, shoveling begins at an advantageous point.

- Experienced miners work out the ground in regular cuts and in an orderly fashion.

- Enough faces are provided so that shovelers will not interfere with one another.

- Provision is made to keep bedrock drained, and boulders and stumps are moved a minimum number of times.

- Cuts are taken of such a width and length that shoveling is made as easy as possible.

- The boxes are kept as low as possible so a minimum lift of gravel is necessary.

- At the same time an adequate slope must be maintained for the gravel to run through the boxes under the limitations of the available water.

- Allowance for dump room must also be provided at the tail end of the sluice.

- Leaks in the sluice are stopped promptly, and shoveling is done in such a manner that the sluice does not become clogged nor does water splash out (Water in the pit hampers shoveling.)All material of a size that will run through the sluice is shoveled in, and the oversize material is thrown to one side.

- Boulders from the first cut should be stacked outside the pit, on barren ground if possible.

- The width of a cut is usually limited to the distance a man can shovel in one operation.

- When shoveling from more than a couple of metres away, it is best to set boards above and on the opposite side of the box; this increases the efficiency of the shovelers.

- The greatest height a man can shovel into a box is 2.5 to 3 metres, and above 2 metres the efficiency of the shoveler is markedly reduced.

- If the gravel is over 1 to 1.25 metres deep, it usually is excavated in benches to facilitate digging and to permit the upper layers to be raised a minimum shoveling height.

- Where the gravel is shallow, wheelbarrows may be used. Another way is to shovel the gravel onto a conveyor belt that discharges into a trommel, discarding the oversize material and running the undersize material through the sluice.

- Where two or more persons are working in the same cut, the height of succeeding benches is governed by the character of the material being dug and the distance the gravel has to be lifted.

The sluice may be maintained on the surface of unworked ground or supported on bents on the opposite side of the cut. After the first cut the boulders are thrown onto the cleaned-up bedrock. Where cuts are run on both sides of the sluice, the boxes are supported on bents as the ground underneath them is dug out. At other places the boxes may be set on bedrock and the dirt may be shoveled into the head of the sluice from short transverse cuts at the upper end of the pit. Work usually begins at the lower end of a deposit so that bedrock may be kept drained, and then proceeds across the deposit by regular cuts. The length and order of the cuts will depend upon local conditions. As heavy sands and gravel build up deposits between the riffles in the sluice, it may be necessary to stir these up to prevent packing and the consequent override of gold particles. A tined implement such as a pitchfork is often convenient for this. Larger stones that lodge in the sluiceway may be similarly removed.

Supplying Water

The quantity of water available will influence the scale of operations and the size of sluice used. A minimum flow of 30-40cm (about 800L per minute) is required for a 30-cm-wide sluicebox with a steep grade. Smaller flows than this can be utilized by storing the water in some kind of reservoir and using the supply intermittently. A common practice followed where the quantity of water is limited is to use a grizzly or screen over the sluice to eliminate oversize material and thus increase the duty of the water. Reduction in the amount of material to be treated by first running it through a trommel to wash and screen out the coarse size is another effective way to lower the water requirements.

Water usually is conducted via ditch to the sluice. However, if the ground is rich enough it may be practicable to pump water for the sluice. The feasibility of obtaining a gravity flow should first be investigated, as the expense of pumping may be more than the cost of a long ditch, when the cost is distributed over the metreage of gravel moved. A suitable number of sluiceboxes or some other removal system may be used to transport the tailings to a dumping ground away from the working area. A tailings or settling pond may be required to maintain downstream water quality.

Ground sluicing

utilizes the cascading effect of water to break down the gravel; hence, the requirements for water are much greater. The chief application of ground sluicing is to streambed deposits. Pipelines, flumes, or ditches would be necessary if ground sluicing were applied to gravels higher up on banks or terraces, and the larger scale hydraulic methods would then become more favorable. If booming is to be done, a dam and reservoir are needed. The dam is usually equipped with a gate mechanism that permits either automatic or manual control and quick release of the impounded water for maximum washing effect. The water may be passed over the upper face of a gravel bank or diverted against the bottom in order to undercut and carry away the gravel as the face of the bank breaks down. All materials are channeled toward the sluice.

The natural flow of a stream can be used by diverting the current with boards or simply with piled boulders. "Shears" can be constructed of 2.5 or 4cm-thick boards 4 metres long nailed to pairs of tripods so that the boards slope back from the water flow at an angle of about 60 degrees. The tripods are built in such a way that boulders can be piled inside the base to hold them in place. A row of these shears may be used to divert the force of the water against a bank, or two rows may be used to form a flume.

The seasonal nature of stream flow in different areas must be kept in mind when planning any placer operation. State and Federal agencies can provide information on stream runoff for many of the more important streams, information which will indicate the limitations in water supply that might be expected due to seasonal changes.

Additional Methods Sometimes Used

The methods described below, particularly the surf washer, are limited in application, but interest in them revives from time to time, so they are included here. Many kinds of dry washers have been developed, some very elaborate. Most dry-washing operations have a short lifespan, owing to the erratic character if the deposits. Skindiving for gold is not new, but development of better diving equipment in recent years has stimulated interest in the method, although restricted in practice to a few select stream areas. Shaft and drift mining are also among methods used in extracting placer gold gravels, but because techniques are more related to other types of mining, discussion is not included in this report.

Dry Washer (for Desert Areas)

Dry washers have been used for many years in Australia, where water is scarce, and especially in New Mexico where several million dollars in gold has been produced during the last century by dry washing. The Cerrillos, Golden, and Hillsboro districts are among those having produced gold by dry washing. In years when other employment is scarce such production may take place widely. In the 1930's a considerable number of men also used dry washers in Nevada, southern California, and Arizona. If gravel is to be treated successfully by dry washing, it must be completely dry and disintegrated. For instance, after rainstorms, operations must be stopped until the ground dries out again. Even in very dry climates the gravel is slightly damp below the surface, and must be dried before it can be treated in a dry washer. Spreading the material to sun-dry or putting it through dryers adds to the cost of mining. In small-scale work, however, the gravel will dry out about as fast as it can be treated.

Dry washers are usually run by hand and have about the same capacity as rockers of corresponding size, but the work of operating the dry washer is much harder. The workers select the material they are to treat with regard to both dryness and probable gold content. It is difficult to do this on a large scale with hired labour. Plants with mechanical excavators and complex power-driven dry-washing machinery have been tried, but in the United States, at least, virtually all were commercial failures, primarily because the gravel was dug faster than the sun could dry it out. Also, in large-scale work, particularly with mechanical excavation, the cost of sizing the material is quite great. Clay and cemented gravel introduce even further difficulties.

When the gold-bearing material is completely dry and disintegrated, panning tests of the tailings should show that a good saving can be made, except perhaps with extremely fine or flaky gold. Completely disintegrated material, however, is seldom obtained. The tops of clay streaks in the gravel are likely to be richer in gold than the gravel itself. Clay or cemented gravel seldom can be broken up sufficiently by hand to free all the gold without the use of some form of pulverizer. In a dry washer all gold included in a lump of waste passes out of the machine. As water usually will break up all the gravel and separate the gold from the other material, a better saving usually can be effected with the rocker or sluiceboxes than with a dry washer.

Basically, the dry washer separates gold from sand by pulsations of air through a porous medium. The screened gravel passes down an inclined riffle box with cross riffles. The bottom of the box consists of canvas or some other fabric. Under the riffle box is a bellows, by which air in short, strong puffs is blown through the canvas. This gives a combined shaking and classifying action to the material. The gold gravitates to the canvas and is held by the riffles, while the waste passes out of the machine.

The gravel is shoveled into a box holding a few shovelfuls at the head of the washer, from which it runs by gravity through the machine. A screen with about 1.25cm openings is used over the box. All stones over about 2.5cm in diameter generally are discarded in mining. A dry washer usually is run by a small petrol engine which saves the labor of one man. The capacity of such machines is considerably greater than that of hand-operated ones. For instance, one man working alone must fill the box, then turn a crank which runs the bellows until the gravel runs through. The process is then repeated. With two men working, one shovels and the other turns the crank. One man can treat 1/2 to 1 cubic m per day with a hand-operated washer, where the gravel lies close to the machine.

When cleaning up, the material behind the riffles usually is dumped into a pan and washed out in water. If water is very scarce, the accumulated material from the riffles may be run through the machine a second time and then further cleaned by blowing away the lighter grains of sand in a pan.

Dry washers are usually handmade and have been built in a large number of designs and sizes. The bellows of the machine is made of 36-ounce duck and the bottom of the riffle box of 8-ounce, single-weave canvas.

In contrast to the single-weave canvas, silk or rayon permits a good extraction of gold, but too much dust goes through into the bellows. Heavier canvas is too tight for good separation. Copper-wire fly screen is used under the canvas. The riffle box is 30cm wide and 1.1m long and contains six riffles. The slope of the riffle box is 30cm to the metre. (Hand-operated machines are usually much smaller and the riffle box is set at a steeper angle than with powered machines.) The gravel and sand are shoveled onto a screen with 0.5cm openings at the top of the washer. The bellows is operated at 250 pulsations per minute; the stroke is 8cm.

The capacity of the machine is about 4/5 metres per hour, which probably would correspond to 1-1/2 or 2 cubic metres, bank measure. (The plus 2.5cm material was previously discarded.)

In cleaning up after treating approximately 1 cubic metre in the washer, the riffle box is lifted out and turned over on a large, flat surface, such as a baking tin. The concentrate from the upper three riffles is first panned, and the gold is removed. Usually both the coarse and the fine gold can be saved here. The lower riffles may contain a few colors, but nearly all the gold is normally caught in the upper riffles.

Surf Washer (for Beach Deposits)

Few sea-beach-type placer gold deposits have been mined successfully. The most important producers have been in the vicinity of Nome, Alaska, but gold is also known to occur in a few other shoreline locations of States bordering the Pacific Ocean. Special techniques have been developed to utilize the action of the surf in recovering gold from these deposits.

Surf washers are similar to long toms, but wider and shorter. They can be used only when the surf is of proper height. They are set so the incoming surf rushes up the sluice, washes material from the screen box or hopper, and retreating, carries it over the riffles and plates. One man can attend to two surf washers, and about 8 cubic metres can be handled per 10 hours.

An example of a simple surf washer is a riffled sluice 1 to 1.25 metres wide and 2.5 to 3 metres long, set on the sand at the water's edge so that the incoming waves wash through it to the upper end, and retreat below the lower end. The sluice is made of boards nailed to sills at either end which can be weighed down with rocks or otherwise. The sides are 6 to 10cm high. The riffles in the example are made in sections of about 2.5- by 2.5cm strips spaced about 2.5cm apart. The end sections are transverse riffles, the center section longitudinal. The box preferably is set on a grade of 10 to 15 cm per 4 metres. Best results are obtained by using mercury in the riffles. When the surf is strong, the washer treats as much as two men can shovel, but at other times it has to be fed very slowly.

Skindiving (Combining Recreation)

In recent years skindiving enthusiasts have taken up small-scale placering as both a hobby and a sometimes, though seldom, profitable venture.Various kinds of apparel and equipment are used, but the investment is usually not great. Wet suits and canvas shoes are almost a necessity for entering cold mountain streams to search the streambed for pockets that might contain gold. Beginners should be equipped with a snorkel, a face mask, gloves, a weighted belt, fins, a gold pan, and a crevicing tool. More experienced divers may use the popular scuba equipment, but this calls for special knowledge to insure safety. Crevicing tools include large spoons, tire irons, crowbars, etc.--almost anything that can reach into tight places and dislodge nuggets from the stream bottom. The pan should be used to test sands from various places where gold would be expected to settle, such as the downstream sides of obstructions. Where colors in the pan indicate a favorable area of the stream, a more intense search may be made.

Mining equipment may include various combinations of pumps, miniature dredges, and riffle boxes that can be built from salvage by the operator or purchased from commercial sources. A number of manufacturers have produced special equipment for the purpose. One of the popular kinds is the jet dredge, a pipelike device made of sheet metal curved at the intake end and with a water jet entry to propel the water and gravel through the straight portion. The jet is supplied from a portable pump and in effect causes gravel and sand to be sucked into and through the pipe. A riffle box built into the end section collects the gold and other heavy particles while the rest of the material discharges. The riffle box may be enclosed so it can function while submerged. Usually, a 6- to 10-horsepower pump is adequate; the hose to the jet may be 3-5cm in diameter.

Manipulating the device underwater requires skill and patience, since the riffle section must be kept nearly horizontal during the mining operation. Floating platforms are sometimes used to support equipment. In this case, riffle boxes and other units may be installed on the platform. The usual operation includes moving many large boulders to get at the trapped gold under neath or alongside. Conventional equipment such as a rocker or a sluice may be employed to carry selected material from the streambed to a shoreline site for processing. Concentrates are then panned to recover the gold.

Problems You Should Anticipate In Placer Mining

Besides the many problems already discussed, such as where and how to find a placer deposit, how to locate a claim, and how to sample and mine, a few special operational problems should be considered. These relate to the physical nature of placer materials and the climatic conditions under which they may be found.

Streams with steep gradients often have poorly sorted sands and gravels, meaning a wide range of size will be encountered, up to cobbles and large, irregularly shaped boulders. Other debris and tree roots may be present too. Materials that have lain in place for long periods become indurated (that is, bound up tightly with clay, or cemented sometimes almost to the point of being solid rock), which makes them exceedingly difficult to break up with water. Irregularities in the rock surface underlying placer materials become important in mining because this is the zone where the richest values usually are found. A very uneven surface can be particularly difficult to work on. In addition, there is difficulty in Alaska where ground may be frozen a large part of the year. It may be impractical for the weekend or vacation prospector to tackle placers where such adverse conditions prevail. How these problems are normally dealt with in larger operations is discussed briefly under the headings to follow.

Handling Boulders

Boulders are best left in place if it is at all possible to work around them. Sometimes, particularly in sluicing, it becomes necessary to move the boulders out of the way. A derrick operated by a hand winch or steam, gasoline, or electric power may be used for this purpose. Possibly several suchderricks will be needed if many boulders are present. Boulders may be drilled with a jackhammer and blasted using dynamite, or more simply blasted with an explosive plastered onto the rock, a technique called "mudcapping." Platform skips may be swung from a derrick boom or cableway; the larger rocks are then pried out and rolled into the skip for removal. A small bucket-loader vehicle may be useful for handling boulders, provided it can operate over the type of surface exposed on the pit floor. Sections of the pit where bedrock has been cleaned up may be reserved for stacking large rocks. Future operations should be planned so repeated handling is avoided.

Trouble With Clays and Cemented Gravels

Clays and cemented gravels usually require the cutting force of the hydraulic giant for effective mining. In some nonfloating washing plants the gravel is delivered to the head of the sluice where a giant is used to break up the clay. Indurated or clayey materials are normally dredged with little difficulty, but if gravels are tightly cemented, they may best be mined by shaft or drift methods using explosives and timbering as required. This presumes they are rich enough to stand the high cost of such mining and are not exposed enough for open pit mining. Clay lumps must be broken up quite thoroughly before passing through gold-recovery equipment because of their capacity to imbed gold particles and carry the gold out with the discharge. The breaking of clays can be accomplished using the puddling box (previously described on p. 29) or with a trommel, which quickly reduces the lumps by its rotation and abrading action. Exposure of clays to air is also effective in breaking them down, although the time required may be a matter of days or weeks.

Cleaning Bedrock

Cleanup of the last remaining materials from bedrock is an important step in gold placering, and if the surface is soft, fractured, or uneven, this can be a painstaking chore. Where bedrock is soft and fractured, gold particles can be embedded as much as acouple of metres, so it often is advisable to also excavate this kind of bedrock material for its gold content. Usually, it is best to clean the bedrock as the work progresses upstream. A final cleaning of the surface may be left until the end of the season, when there is more time to spend on this activity and when the water is short for other work.

Where bedrock is hard it must be cleaned largely by hand, and the soft seams and cracks invariably present should be cleaned out with hand tools. A hose and small pump are almost necessities for a good cleanup. Sometimes a separate sluicebox smaller than that used in the main operation will be employed for handling materials from a cleanup operation.

Recovering Your Gold And Selling It

As you reach the final stage in turning arduous labours into a product, the gold should be in either of two forms--a nearly pure concentrate or an amalgam with mercury--depending upon whether the latter was used to implement the collection of gold. Placer gold in its natural form is almost always alloyed with a certain amount of silver, which decreases its fineness. The silver, being much lower in value or price per ounce, lowers the value of the gold by a corresponding amount. Fineness is based on a scale of 0 to 1,000. As an example, gold 750 fine would be three-fourths gold and probably close to one-fourth silver. The important thing is that the gold until it is refined will be worth somewhat less than the market price for pure gold. The exception to this, of course, is specimen material that may have special value in its natural form.

Gold in an amalgam can be heated or retorted to drive off the mercury, leaving a gold sponge. Great care should be taken when this is done to avoid inhalation of the mercury fumes, which are highly toxic and which can cause a variety of ailments or even death. Small quantities of amalgam may be heated on an iron surface, such as a shovel face, out-of-doors where the vapors will be quickly dispersed. Preferably, a retort is used for environmental reasons and personal safety. Mercury, which partially vaporizes at ordinary room temperatures, will vaporize completely at about 675 degrees F, so an ordinary fire or propane burner will suffice. Small retorts are commercially available, or they can be constructed out of a small cast iron pot with a tight-fitting cover to which a short length of water-jacketed condenser pipe is connected.

A typical setup may have a sloping pipe 0.5 to 1.4 metres long encased in a larger diameter pipe through which water is circulated. A coating of chalk or clay inside the pot will prevent the gold from adhering to the iron. The pot is heated gently at first, raising the temperature gradually until mercury stops coming from the condenser outlet. Mercury thus recovered is ready to reuse for amalgamation, and the spongy mass of gold can be sold. Because amalgams are difficult to sell, it is usually best to retort your own and market the gold.

Gold is priced and sold by the troy ounce, which should not be confused with the better known avoirdupois ounce. A troy pound consists of 12 troy ounces and is equivalent to 0.8229 pound avoirdupois. A button of gold that weighed 1 pound avoirdupois would contain about 14.6 troy ounces. Normally, gold is weighed on special troy scales so the confusion in this odd conversion is eliminated.

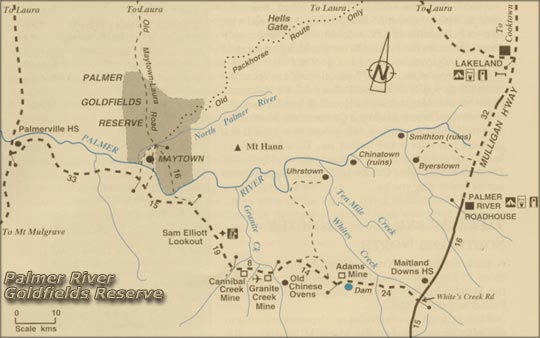

The Palmer River Gold Fields

The Palmer River goldfield was first gazetted on 27 November 1873. The main mining centers were in Maytown, Palmerville and Jessops Hill with the goldfield totalling an area close on 9000km square.The Palmer and all of its tributaries were worked from the junction of Campbell creek (65km north of Maytown) to Strathleven. The most productive region was between Byerstown and Fish Creek Junction.

Some of the creeks and gullies worked were Jessop's, Sandy, Cradle and Oakey Creek. Locations such as Revolver Point, Milkmans flat, McGann's and White Horse all yielded plentiful gold.

With a large population of Chinese diggers it was hard to tell what the total gold removed was, as the Chinese often sent their winnings home in burial jars. At the time, gold prices in Australia were around 3p 17s an ounce and the same gold in Hong Kong went for around 5 pound per ounce. The total estimated return was somewhere around about 1,333,893 ozs. of gold.

A good place to start looking would be in Maytown as every creek and gully for a radius of 10km yielded gold . Overall the soil cover averages a depth of 30cm which means that most detectors could easily find any nuggets left behind by the old timers.