Ancient Roman Mining

Ancient Roman Mining

1. Roman Mining

Introduction

Types of Roman Mining

Mining Tools

Underground workings

Special Problems of Deep-vein

Mining

Conclusion

2. Roman Silver Mining

Introduction to Roman Silver

Mining

Geologic Background

Roman-Age Mining

Many Forms of Contamination

Remaining from the 2,000-Year Old Mining and Metallurgical Industry

Postulated Airborne

Heavy-Metal Plume

Summary

References Cited

Acknowledgements

1. Roman Mining

Introduction Roman Mining

The Romans mined for metals in every part of their empire. They sought

both utilitarian metals such as iron, copper, tin, and lead, and the

precious metals gold and silver. The desire for mineral resources may even

have affected foreign policy. Before he invaded, Caesar knew of the rich

tin deposits in Britain, a metal used in the production of bronze and in

limited supply elsewhere in the empire [Caesar, 5.12].Our knowledge of Roman mining comes from modern excavation reports of the mines and from literary sources, such as Diodorus of Sicily and Pliny. The written evidence does not discuss all aspects of mining, leaving out information such as how veins were located, what tools were used, or how drainage wheels were used to control water. When an author mentions a mine, it is rarely with enough information to identify an exact location. The mines themselves contain evidence for various processes, but we must interpret the remains. A number of Roman mines have been excavated and documented. Examples include the gold mine at Dolaucothi in Wales, and the extensive silver workings at Rio Tinto, Spain. Mining is a destructive process, so much evidence has been erased by Roman and later working. It is particularly difficult to date features such as shafts and tools. Some earlier mines, such as the Greek silver mine of Laurion, had a Roman period that may have had minimal effect on the mine features. The poor preservation of organic remains also limits the information. In Dolaucothi, for example, the investigators believe that only one board of a wooden drainage wheel survives in the mine because the other parts were burned in a fire set to loosen rock [Boon, p. 123].

Types of Roman mining

Despite these limitations, it is possible to develop a picture of Roman mining. The Romans employed three techniques to recover the metals. Pliny describes them"Gold in our part of the world ... is found in three ways: first, in river deposits. ... No gold is more refined, for it is thoroughly polished by the very flow of the stream and by wear. The other methods are to mine it in excavated shafts or to look for it in the debris of undermined mountains." [XXXIII 66; Humphrey, et al., hereafter SB, p. 187]

The least difficult was surface mining, where the ore was available at the surface either in streambeds or exposed on the ground. The erosive power of streams broke up the ore and the heavier metals settled to the bottom in areas of slower flow. These are called placer deposits. Where the Romans recognized metal ores on the surface, they could follow them into the ground by strip-mining the surface ("the debris of undermined mountains"), or digging short tunnels. This technique, called opencast, was used for many metals.

The third technique, deep-vein mining, was the most difficult and dangerous. Only gold and silver were valuable enough to justify digging underground. After a suitable site was found, tunnels were excavated in the rock to remove the ore. Narrow vertical shafts were driven through the rock, widening out to horizontal galleries where the ore was found. Sometimes horizontal adits from a hillside were driven as well. Working below ground, the miners had to deal with the need for lighting, the dangers of poor ventilation, and the presence of water in the tunnels. Figure 1 shows the structure of a hypothetical mine.

Figure 1

This report describes the characteristics of deep-vein mining, as well as the special problems involved. In addition to the writings of a number of Roman and Greek authors, the data come from archaeological excavation reports of Roman mines in Britain and Spain. This information is compared to practices described by Agricola in the 16th century, and activities at the colonial Reed gold mine near Stanfield, North Carolina.

The Romans lacked a theoretical knowledge of geology, but they (and the Greeks before them) made observations that helped them locate ore sources. Pliny [XXXIII 67 and 98] mentions the association of particular earths with ore. Sometimes they pursued the source of placer deposits upstream to the side valleys [Davies, p. 17]. They recognized the affinity of one type of metal for another [Pliny, XXXIII 95] and that metals often occurred where different layers came in contact [Davies, p. 17]. They made limited use of adits for prospecting [Diodorus, 5.36]. All of these methods helped the Romans locate possible deposits. The same techniques were used at Reed mine, where a placer find encouraged surface digging, and eventually the excavation of adits and shafts in the hill. Colonial prospectors relied on surface signs much like those the Romans observed.

Mining Tools

Removing rock was a difficult and time-consuming process in Roman mines. Iron was used for most tools, though stone hammers and wedges have been recovered [Davies, p. 35-36]. When mining hard stone, an iron gad (a pointed bar) struck by a hammer would remove stone in flakes and dust. This gad could be socketed for a handle, held in miners' hands, or gripped with tongs [Davies, p. 32]. The Romans used single and double headed hammers weighing 5-10 pounds, with sockets for a wooden handle [Healy, p. 100]. Iron picks, usually with an 8-9 inch curved blade, were used to work softer rock [Davies, p. 32]. Other iron tools include crowbars [Davies, p. 33], battering rams ["they...batter the flint with rams carrying 150 pounds of iron", Pliny, XXXIII 71; SB, p. 188], and wedges ["they attack it with iron wedges and the rams mentioned above", Pliny XXXIII 72; SB, p. 188]. Roman mining tools excavated from Baetica, Spain are shown in Figure 2. On the bottom row are examples of a pick and a hammer.

Figure 2 [after Shepherd, p. 21]

The iron tools of the miner did not change into the colonial period. Agricola mentions using a gad like those found in Rio Tinto and Laurion [Forbes, p. 194], and the mine tour at Reed mine included a demonstration of how rock was removed with a gad and hammer.

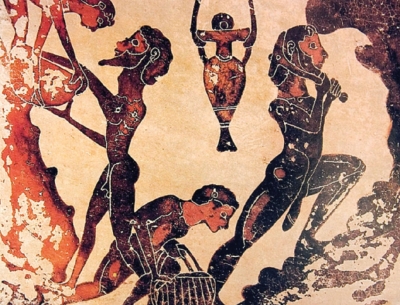

Ore freed from the walls could be gathered into baskets or buckets with iron rakes, spades, or hoe-like mattocks [Davies, p. 33]. Baskets of esparto grass have been recovered from Spain [Davies, p. 30], and wooden trays were found at Rio Tinto [Craddock, p. 83]. From the Greek mine of Laurion (later lightly worked by the Romans) came a bronze bowl [Davies, p. 30]. Figure 3 is a 6th century BC Greek plaque showing miners using ore baskets and a pick [Shepherd, p. 35]1.

Figure 3 [after Shepherd, p. 35]

We have relatively few wooden or textile items surviving from Roman times. But in the mines, we occasionally find conditions in which these are preserved. Wood was used for buckets to remove ore [Davies, p. 30]. Several wooden ladders remain, as do wooden water-lifting devices (described later). The existence of wooden wedges is inferred from a large gallery at Linares in Spain that has no tool marks on it [Davies, p. 20]. These wedges would swell when wet, cracking the rock. Leather sacks, miners' sandals and caps have also been recovered [Healy, p. 101].

At Palazuelos, Spain, an area where the Romans mined silver, was found a sculpted relief (Figure 4). It shows miners dressed in tunics with aprons of (presumably) leather to protect themselves [Rickard, JRS, p. 140]. The largest miner carries tongs in one hand, and an oil can or bell in the other. Another miner carries a type of pick, and another a lamp [Sanders, p. 321]. The depiction fits well with the mining equipment recovered from Roman mines.

Figure 4 [Davies, illustration 42]

Underground workings

With these tools, Roman miners dug vertical shafts and horizontal galleries and adits. The passages were small due to the difficulties of removing the rock. Diodorus describes mining,"...opening shafts up in many places and digging deep into the earth, [they] search for the strata rich in silver and gold.

They carry on not only for a great distance, but also to great depth, extending their diggings for many stades and

driving on galleries branching and bending in various directions, bringing up from the depths the ore which provides them with gain." [5.36-38; SB, p. 186]

Iron tools such as the pick or gad were used to make an initial groove, and then other tools (wedges, chisels, picks) broke away the exposed ridge [Davies, p. 20]. The Roman authors do not describe this process, but it is presumably similar to quarrying blocks of building stone. It was hard work: "those individuals of outstanding physical strength break up the quartz rock with iron hammers, applying to the work not skill, but force" [Diodorus, 3.12-13.1; SB, p. 184].

Shafts were vertical or inclined passages that provided access, ventilation, and a path for ore removal. They were normally square, small (1-2 meters square), and braced with wood to prevent collapse. The circular shafts were lined with stone. The square shaft at Reed mine was similarly reinforced by timber. Many Roman shafts contain foot- or handholds for climbing, and a few ladders have been preserved [Davies, p. 23]. A shaft could be as much as 200 meters deep [Rickard, Metals, p. 447], but most are less as the placement of the ore body determined their depth. In addition to vertical shafts, horizontal adits might be driven from the hillside in to the ore body. Some adits were for ore removal, some for drainage.

From the initial shaft, horizontal galleries could be driven at depth. The galleries followed the veins as they wove underground. The outline of the galleries was rectangular, with a height of only 1 - 1.5 meters and a width about 1 meter [Shepherd, p. 17]. There were some tunnels that were even smaller: "It is not possible for someone to stand upright while digging in the Samian deposits, but he must dig while on his back or side" [Theophrastus, On Stones 63; SB, p. 185]. Although he is referring to mining for clay, many galleries at Laurion were very cramped. Some galleries, such as at Rio Tinto and Dolaucothi, were slightly larger near the roof, perhaps to accommodate the men's shoulders or ore baskets borne at shoulder level [Rickard, JRS, p. 132; Manning, p. 301]. Rarely galleries were quite long, such as the 2.2 km ones Pliny ascribed to Hannibal [XXXIII 96].

The galleries were supported by wood bracing, called 'propping' ["The earth is held up with wooden supports", Pliny XXXIII 68; SB, p. 187] or by pillars of unmined rock. The rock pillars were critical, and there was a penalty of death if these were mined [Plutarch, 843d]. The danger of roof collapse was always present, as evidenced by the crushed skeletons found in Asia Minor and a passage by Statius describing a miner crushed under the rock [6.880-885]. In the lex Vipasca (a contract for the lease of the imperial mines, second century AD), wood propping was obligatory [Bruns, p 293-5; SB, p. 180.]

Besides the iron tools, the Romans used fire to fracture the rock for removal. Pliny mentions breaking up flint by means of fire and vinegar [XXXIII 71], and Diodorus talks of "burning the hardest of the gold-bearing matrix with a great fire and making it friable" before crushing the stone by hand [3.12-13.1; SB, p. 184]. Many ancient authors, including Livy [XXI.XXXVII.2] and Vitruvius [VIII.3.19] mention fire-setting and vinegar. The vinegar would have produced additional fracturing from the rapid fall in temperature. Modern geologists question the value of the vinegar over any other cold liquid [Craddock, 33-35; Shepherd, p. 23-24], but given the frequent mention made of it, vinegar was probably used. Fire-setting continued to be done through Agricola's time [Craddock, p. 34], until explosives were developed. At Reed mine, black powder was available and fire-setting was not used.

Once broken up, the ore had to be brought to the surface for further processing. Diodorus [3.13.1] mentions boys scrambling through the tunnels, and Pliny [XXXIII 71] describes a relay of miners carrying the ore out on their shoulders. Figure 3, the Greek plaque, shows smaller individuals handling the ore baskets. Presumably the boys could move more easily in the low-ceilinged tunnels. Baskets, buckets, sacks or sleds would have been filled with ore and transported either to an adit mouth or the bottom of a shaft. The Romans did not use a wheeled cart, as Agricola described, but wooden trays from Rio Tinto look like those published in Agricola's De Re Metallica [Craddock, p. 83]. Once at the shaft bottom, the ore could be carried up with the miner, using the ladders or handholds cut in the sides. Alternatively, the ore container could be raised with a rope. Rope marks on shaft sides are taken as evidence of this [Shepherd, p. 43-44]. There is evidence for a wheel or windlass at the top of a shaft from Rio Tinto [Healy, p. 102]. Ore was raised up the shaft at Reed mine by a rope attached to a "kibble", an iron bucket. The colonial practice is quite close to the Roman one.

Special problems of deep-vein mining

Ventilation

The deep mine workings created problems with ventilation, lighting, and drainage. The Romans knew the dangers of bad air in the mines. Pliny writes, "The fumes from silver mines are harmful to all animals" [XXXIII 98; SB, p. 175], and "when well shafts have been sunk deep, fumes of sulfur or alum rush up to meet the diggers and kill them" [XXXI 49; SB, p. 190]. Similar passages occur in Lucretius [6.808-815], Strabo [12.3.40], and Vitruvius [8.6.12]. The latter author mentions lowering a lamp into a (well) shaft to determine if the air is dangerous.In addition to bad air, the mines were hot. For every 30 meters deeper, the temperature increased 1 degree Centigrade [Healy, p. 82]. The depiction of Greek miners (Figure 3) working naked shows that heat was a common problem. The use of fire-setting (described above) to drive galleries could only have added to the ventilation problems.

To overcome the problems of heat and toxic gases, the Romans created additional air movement through convection. This could be done by cutting additional shafts in parallel, as was done at Rio Tinto [Davies, p. 24], so that the warmer air from the mine rose and was replaced by cooler air from outside. Theophrastus described this, "They make ventilation shafts, so that the air is thinned by movement" [Concerning Fire 24; SB, p. 190]. Vitruvius, in the same passage that described the lighted lamp down the well to detect gases, says "but if the flame is snuffed out by the power of the gas, then ventilation shafts are to be dug next to the well on either side. In this way the gas vapours will be dissipated through the shafts as through nostrils" [8.6.13; SB, p. 289]. Davies [p. 24] thinks shallow grooves on some shaft walls were used for boards to separate a single shaft into an up and down draft. Fires could also be set to increase air movement, a practice mentioned by Theophrastus [Concerning Fire 70], but these would have to be carefully placed to avoid adding to the ventilation problems. Interconnecting galleries and frequent cross-cuts as found at Rio Tinto would also have increased air flow [Davies, p. 23-4]. Pliny refers to waving linen strips [XXXI 49] to move the air, a practice also illustrated by Agricola [Craddock, p. 75]. Poor ventilation remained a serious problem in Roman times.

Lighting

The miners often spent long periods in the dark, with only oil lamps for lighting. Pliny says that the lamps measured the periods of work [XXXIII 70], perhaps a daily shift of 8 or 10 hours. The miners used oil lamps like those found in Roman homes. These were stone or terracotta dishes with a wick [Figure 5]. The lamps were found in niches in the walls [Forbes, p. 210]. Diodorus [3.12.6] mentions lamps mounted on the miners' heads, but there is no other evidence of this. At Reed mine, the candles were worn on the heads of the miners. Mounting the lamps would bring the light where the miner needed it. Torches could have been used for light as well, but they would have added to the ventilation problems.

Figure 5 [after Shepherd, p. 41]

Drainage

The control of underground water could determine the viability of a mine. This water comes from percolation from above the mine, or more rarely, from digging into the sea or a subterranean river [Shepherd, p. 35]. Many mines simply stopped at the water table. Mines that went below quickly filled with water when abandoned. While they were being worked, the Romans used several methods for handling the water. They could drive drainage adits below working levels, use slaves to bail the workings, or employ one of two mechanical devices.Diodorus states that "at a depth they sometimes break in on rivers flowing beneath the surface whose strength they overcome by diverting their welling tributaries off to the side in channels" [5.37; SB, p. 186]. Occasionally water could be diverted into a natural fissure, but the miners drove artificial channels as well. Drainage adits, also called cross-cuts, are found at some sites such as Dolaucothi and Rio Tinto [Davies, p. 24]. Water drained from upper workings into the adit, but during the digging of the adit, the water had to be handled by another method.

Where the flow was not strong, and labor was available, bailing could control the water. Pliny tells of Hannibal using a line of water-bearers along a 2.2 km gallery [XXXIII 97]. Baskets of esparto grass waterproofed with pitch, and bronze or wooden buckets, have been found in the mines [Forbes, p. 211]. The buckets could hold 150 liters and their bottoms were pointed so they tilted automatically to be filled [Davies, p. 25]. Their shape and weight when filled suggest that they were hauled out of the mine by means of a winch.

From the first century AD, Roman miners had access to two water-lifting devices. The earlier one is the Archimedean screw, or cochlea. Diodorus describes the use of the screw:

"They draw off the streams of water with the so-called Egyptian screw, which Archimedes the Syracusan invented when he visited Egypt.

By means of these devices, set up in an unbroken series up to the mouth of the mine, they dry up the mining area and provide a suitable environment for carrying out their work. Since this device is quite ingenious, a prodigious amount of water is discharged from the depths into the light of day" [5.37; SB, p. 186].

Vitruvius [10.6.1-4] described the construction of the screw in detail. It consisted of a hollow wooden cylinder (the case) with a wooden helical screw inside (the rotor). The rotor had wooden or copper vanes, around a central wooden core, which was attached to the case with an iron pivot. A single person, treading on the cleats around the center of the case or turning a crank, could operate this screw and raise water from one end to the other. A 3 meter screw would raise water approximately 1 meter, and they were often placed in series to raise water to a drainage adit [Craddock, p. 78-79].

Vitruvius specified an angle of 37Ëš for the screw from the ground. Various inefficiencies reduce its output. There was friction in the rotor shaft bearings, and some water loss due to the uneven movement of the rotor. Landels estimates the efficiency at 40 - 50%, which would produce 35-40 gallons per minute when the screw is mounted as Vitruvius specified [Landels, p. 63].

Contemporary depictions of screws in use are known from a Pompeii wall painting [Forbes, p. 213] and an Egyptian terracotta [Rickard, Metals, p. 425], but neither portrays a mine. A number of screws have been recovered from Roman mines. An example from Sotiel Coronada, a Spanish mine, is 3.6 meters long and 48 centimeters in diameter, and was one of three in series [Forbes, p. 214]. One screw poured water into a sump, from which the next screw moved it further upward. One screw from Centenillo was slightly larger: length 5 m, diameter 59 cm with a core 20 cm thick [Shepherd, p. 40]. The angle of the Coronada screws is 15-20Ëš, while those from Centenillo were 35Ëš [Davies, p. 28]. The difference in size may have affected the angle chosen. One from Alcaracejos had an iron crank for turning [Davies, p. 27]. With Diodorus' account, and archaeological evidence from a number of mines, the screws appear to have been in widespread use in the Roman Empire.

The other water-lifting device, the water-wheel, came into use slightly after the screw. Unlike water-wheels familiar from colonial sites, this was powered by men rather than by water. Vitruvius described two types, one with a compartmented body and the other with a compartmented rim. His description of the latter:

"A wheel will be built around the axle, of a large enough diameter so that it can reach the height which is required. Rectangular compartments will be fixed around the circumference of the wheel and made tight with pitch and wax. Thus, when the wheel is turned by men treading it, the containers will be carried up full to the top of the wheel and on their downward turn will pour out into a reservoir what they have themselves raised [10.4.2; SB, p. 311]".

On the compartmented rim wheel, the rim contained sections with holes for the water to flow in and out. At the bottom of the course of the wheel, the hole was submerged in the sump and the compartment filled. Near the top, the hole discharged the water into an adjacent trough, called a launder (Figure 6). Archaeological remains are compatible with Vitruvius' description [Boon, p. 124].

The wheels found are usually 4-6 meters in diameter with 20-24 compartments. Each has an axle of bronze or wood, and an oak hub around the axle. Spokes, secured with tree nails, connect the hub and compartmented rim. Numbering found on a Roman wheel from Rio Tinto suggests that the wheels were prefabricated in a more spacious location, before being erected in the mine. The rim was continuous with dividers (Figure 6), rather than containing separate buckets that carried the water. On the outside of the compartments were wooden cleats [Shepherd, p. 37-8].

Vitruvius mentions that men tread on the water-wheels to turn them [10.4.2], but gives no specifics. Wear patterns on the cleats confirm that some wheels were turned this way (Figure 7). Some cleats project from the side of the rim, parallel to the axle. These wheels could be turned by hand or pushed by men's feet. One wheel in Tharsis (Spain) had bits of rope surviving, suggesting it could be pulled by hand [Shepherd, p. 37-8].

The wheel could raise water higher than the screw, but moved less water per minute. The height raised was approximately 3/4 the height of the wheel, limited by how water fell from the compartment holes near the top of the rise, and also by the depth the wheel reached into the sump. The wheels delivered approximately 19 gallons per minute for a 12-foot rise [Landels, p. 69]. Landels calculated that the power required to operate a wheel would be 0.1 hp, which one man could produce and continue to produce over 8 hours [p. 69].

Though constructed mainly of wood, waterwheels are preserved at a number of Roman mines. Part of a water wheel was found in the Dolaucothi mines of South Wales, 9 wheels were found at San Domingos in Portugal, and other examples are known from Dacia [Davies, p. 26-7]. Wheels were often used in series so that the output of one wheel became the input of another. At Rio Tinto, 8 pairs of wheels in series were found, which combined could raise water 30 meters [Forbes, p. 217]. The counter-rotating pairs of wheels (Figure 7) reduced the turbulence and decreased the slight downward slope required for one pair to feed the next level [Healy, p. 99]. Whether in pairs or as singles, special sump chambers had to be excavated in the mine to hold the wheels. Water control was a serious problem for the Roman miner, and all the possible solutions (except abandonment) required a substantial commitment of resources.

Conclusion

Deep-vein miners had to deal with a number of difficult problems, including drainage, ventilation, lighting, and safety. Comparison of the Roman, medieval, and colonial practices shows that many techniques remained the same up to the last century. Likely mine sites were identified by surface finds. Ore was extracted and removed by iron hand tools, and lifted up the shaft using a rope. In the 16th century, miners were still using fire-setting and wooden trays. In 1600 years, mining technology progressed very little beyond the Roman practices.Questions?

email: duncanl@cs.unc.edu Roman Silver Mining - More

than broken jars and roof tiles, the environmental legacy of a Roman

mineral industry

at Plasenzuela, Extremadura, Spain

Introduction Roman Silver Mining and Pollution

While industrial contamination of the environment in the Americas is mostly limited to post-European settlements, a significant metallurgical industry yielding voluminous toxic waste was well established in the Old World by 2500-2000 years ago (Nriagu,1998). Attention has been drawn to the magnitude of this industry by the substantial increase in worldwide atmospheric lead attributed to Greek and Roman smelting of lead-silver ores from about 2,500 years before the present, and recorded in Greenland glacial ice cores (Hong and others,1994), in Swiss and Spanish peat bogs (Shotyk and others, 1998), and in Swedish lakes. Pyatt and others (2000) have also studied the persistence of toxic metals in an area of ancient mining and smelting and the potential influence on the environment.

The Plasenzuela silver-lead district in Cáceres Province, Extremadura, in west-central Spain was exploited by Roman miners for roughly 100 years starting about 30-20 B.C., and by modern miners from the 1850's to 1908 (Domergue, 1987). We see evidence of extensive smelting in the district only during the Roman period. Significant amounts of the toxic metals lead, zinc, arsenic, cadmium, and copper persist in mine waste-rock dumps of probable Roman origin, and in dumps of smelter slags certain to be Roman. Metals from both Roman-age and modern mining industry have been dispersed widely in the surrounding environment,and especially in associated soils and plants and river alluvium. An extensive area where soil lead concentrations exceed the normal regional background of 40 ppm at many sites remains unexplained, but some of it may be the result of air-borne deposition of fumes from the Roman smelting furnaces.

The Plasenzuela Project studies the retention and dispersion of metals into the environment from all sources, but especially from the two millenia old Roman industry, providing a time span not available in the Western Hemisphere. The relatively simple history of the district and the lack of subsequent disturbance of part of the ancient wastes make this area an ideal site for such a study. The project is multidisciplinary, involving geologic, geochemical, geobotanical, and archaeo-metallurgical methods, and compliments current studies of much younger mine waste problems by the U.S. Geological Survey and its Spanish counterpart, the Instituto Tecnológico GeoMinero de España.

Geologic Background

The ores were originally deposited as sulfides in narrow, nearly vertical veins, formed in a sequence of tightly folded slates and graywackes. The gangue, or non-useful, minerals in the veins was mostly quartz and carbonates. The upper parts of the veins, perhaps the upper 60 meters, would have been oxidized by surface waters. Important changes in the smelting process may have been required when the Roman mines reached below the oxidized ore zone and extracted the sulfide ores at greater depth.

Roman-Age Mining

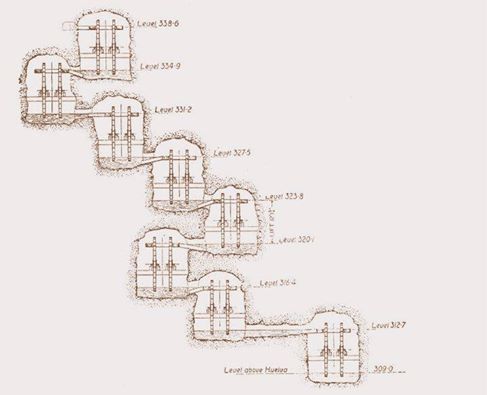

Cross section of Roman underground mine might have looked like this.

The Roman-age miners extended their underground workings to a depth of at least 137 m, or perhaps 80 meters below the water table. Shallow pits and trenches were surely common as well, but are now mostly obscured or not recognized. The ancient mines operated from about 20 B.C. to about 80 A.D., or during the reigns of the emperors Augustus through Vespasian. The Roman-age workings were best observed when the modern mines were operating and a few Roman artifacts were recovered from depth. Safe examination of the Roman mine workings would yield invaluable information, but is beyond the resources of the present project.

The Many Forms of Contamination Remaining from the 2,000-Year Old Mining and Metallurgical Industry

At the outset of the Plasenzuela Project, we expected to find significant amounts of metals in the mine waste-rock dumps and in the smelter slags, not realizing that measurable contamination is also present in vegetation, in downslope sediments leading into the river, in alluvium of the Río Tamuja downstream for at least 18 km below the last mine, and probably in aqueous mine drainage. Soils on a ridge crest north of the smelters, in a partly delineated area at least 200 meters long, contain as much as 1200 ppm lead and elevated zinc and arsenic. Some of this may be related to substrate mineralization, and we are awaiting analytical results from a broader sample net and from many samples taken in test holes augered to 40-80 cm depth. Previous analyses show that metal levels increase in depth at some sites, but decrease at others. Possibly some of the metals are derived from fallout from the ancient smelter gases.

Bed of the river with the typical pasture land in the background. The botanist in the picture has just collected a sample of river sediment for chemical analysis.

Metals remaining in the mine-waste rock --

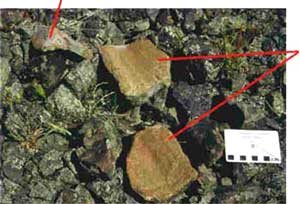

Differentiation between ancient rock dumps and small well-weathered modern dumps is difficult. All suspect Roman mine-waste is now mostly earthy, with fewer and smaller fragments of slaty rock than dumps that are clearly modern. Some slate fragments have percussion marks that we believe indicate that they were extracted by using a small pick. At one site, several heavily patinated metallic lead fragments were found 10-20 cm beneath the surface. Limited archaeological excavations to more-surely verify the ages of waste-rock dumps are included in our future project plans.

| Soil sample collection points. Soil

from the middle site contains 1.3% lead. but the vegetation here

shows no obvious effects of the toxic metal and the oaks have

taken up little of the lead. (See also Anderson and others, 2000,

regarding lead uptake by oak trees near smelter sites.) |

Piles of weathered waste rock from suspected Roman mine. |

There is as much as 20,000 ppm (2.0%) lead, 7000 ppm (0.7%) zinc, and 5000 ppm (0.5%) arsenic in the dump soils, much higher than soils over similar rock outside the mining area where maxima rarely exceed 40 ppm lead, 115 ppm zinc, and 100 ppm arsenic. Soil sample transects on the dump surfaces and extending downslope below them indicate that metals continue to be transported into the local drainage systems. While the total affected areas are relatively small, they are more than sufficient to demonstrate the potential persistence of toxic metals in favorable soils. They make up only small portions of large pasture areas and generally provide but scant forage. Estimation of potential human impact is premature.

The lead-zinc smelter slag --

Smelting was carried out in an area 700 m long close to the RíoTamuja, now marked by several thousand tons of smelter waste. We have not found the furnaces themselves, but there are scattered pieces of granite furnace wall coated with slag, and places on the bedrock surface where we think that furnace bases rested.

Smelter slag dump surface. The slag here is estimated to be 2-3 meters deep.

| Edge view of Roman roof tile fragment showing how the edge is thickened.

|

Roof tile fragments with typical raised and thickened edges. Surface of the smelter slag dump. Three pieces of weathered and rounded Roman roof tile rest on the surface. Unworn, sharp-edged tile fragments buried within the slag are our best confirmation of the Roman age of the slag dump. |

The slag, a waste product of smelting incorporating most of the unwanted elements in the ores, here consists of platy pieces 1-3 cm thick with wrinkled or bubble-pocked upper surfaces,the largest pieces up to 25 cm long, and thicker irregular chunks.

Slag on surface of the Roman dump.

It was tapped or allowed to flow from the furnaces and solidify outside in round shallow molds. Most of the slag is dense and dark gray to black and appears stony or visibly crystalline; sparse fragments are glassy, and some consist of translucent glass enclosing minute bundles of acicular crystals near fayalite in composition. Large vesicles, one-half to two-cm thick and several cm in horizontal dimension, are common, and some of the thicker chunks appear to be built up of multiple taps into the same basin with several parallel horizontal vesicles. We are puzzled that in examination of great numbers of slag pieces, we have recognized no spaces in the slag where the molten metal seemed to have formed.

Evidence for Roman origin of the smelters and slags --

Uneroded Roman roof tile fragments are found deep within the slag piles. Roswag (1853), who had access to the ancient mines before modern mine development began, regarded the slag as Roman in origin. There is no evidence for significant smelting in the district since Roman times.

Fragments of a Roman roof tile found near the smelters. The heavy raised edge of the tile is believed to be unique to the Roman era.

Sketch of Roman smelter as we suppose it looked. This tall-furnace model is adapted from Conophagos (1982), and Jones (1984). They proposed that such furnaces were used for Greek lead-silver smelting before 400 B.C. No such tall models have been reported by archaeologists in Spain, but were suggested by Strabo.

| The question of glassy coatings on certain roof tiles near the furnaces -- Toward the end of our latest field season we noted that many pieces of Roman-design roof tile in the area of the slags were coated with a layer of very hard, crusty material. Generally dull gray on the surface, the broken edge of the crust appears vitreous and dark gray to black. In one piece that we had analysed, the coating proved to be more than 40 percent lead. Ten other samples were tested with a simple field test for lead and all were strongly positive. The lower surface of each tile, that opposite to the raised rim (see figure below), has more of the coating and has formed drips which indicate that the orientations of the tile fragments were always the same, and in a high-temperature environment, but not as hot as the zone where smelting took place. They are so common that their placement must have been intentional and purposeful. In a book called "King Croesus' Gold," (Ramage and others, 2000, p. 161), lead oxide-coated ceramic fragments shaped much like Roman roof tiles were called "bread trays". These were consistently coated with lead oxide on the side of the raised rim. The authors believe them to have played a role in the cupellation process. We wonder if deliberate placement of the tiles as shelf-like projections in a cupellation hearth or furnace structure had been an attempt to recover some of the gaseous losses since there was surely considerable loss of lead and silver during both smelting and cupellation. It is intriguing to speculate that Roman and even earlier metallurgists might have recognized this manner of metal loss and sought to reduce it. |

Typical roof tile fragments associated with lead-silver smelting sites in the Plasenzuela district and coated with a lead-silver-rich crust or film. We suggest that these tiles were placed to extend inward inside a metallurgical structure, perhaps a furnace stack or a cupellation hearth, and the crusts to have been precipitated by the metal-rich exhaust gases.

| Separation of silver from the lead-silver alloy -- Two molten fluids were tapped from the furnace and allowed to solidify in a small basin shaped in the ground or in finely-broken slag: a lead-silver metal alloy which was the most dense and would have settled on the bottom, to be overlain by the slag, a semi-glassy largely silicate material. The silver metal was then separated from the lead by cupellation, a process already ancient in Roman time. The metal was placed in a shallow open basin or ceramic bowl (the cupel) in a furnace and a strong blast of air blown across the surface of the molten metal. The lead oxidized to form PbO (litharge, from Greek for the "spume of silver"), the relatively pure silver remained as metal. The litharge could then be recycled through the smelting furnace to recover the lead metal. For more extensive discussions of ancient silver smelting and cupellation, see Craddock (1995). We have found no litharge near the smelters in our area, and no ceramic vessels that might resemble cupels, nor other evidence that cupellation was carried out at this site. However, field evidence of cupellation has been mentioned by Roswag (1853) and Domergue (1987). We have found a plate of litharge on a mine dump a kilometer distant. |

Heavy metals in the slags --

Most slag samples contain 5-7% lead, 3-7% zinc, and 0.02-0.04% arsenic. Ores here are arsenic-rich, but much arsenic would have been vaporized in the smelting process, hence there is relatively little in the furnace products. As with the waste-rock dumps, soil and dissolved metals are transported downslope and eventually into the Río Tamuja. Located close to the Río Tamuja, slag continues to be swept from the piles in major floods and is present in river gravels as far as 23 km downstream. However, many thousands of tons of slag remain.

Soils interstitial to the slag fragments contain 1.5-2.3% lead and 0.3-0.6% zinc, thus the Pb/Zn ratio is higher in the soil. These metals may be contained in fine smelter waste in the soil, or perhaps leached from the slag fragments.

The Postulated Airborne Heavy-Metal Plume

Soils at many sites that seem well removed from mining or transportation activity as well as from mineralization, nevertheless contain anomalous lead. Soil analyses at 323 sites in the southern part of the district delineate an area where the lead in many samples exceeds 40 ppm, the normal background in the region. The anomalous area crosses rock types, diverges from the trend of mineralization, and extends northeastward, the probable prevailing downwind direction.

Map of lead in soils, showing area of enrichment. The sample sites were selected to be free from direct contamination by mineral industry operations or natural mineralization.

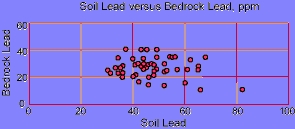

Graph of Soil Pb/Bedrock Pb in 55 composite sample pairs of soils and rocks each collected from 10 m diameter areas. Analyses of these sample pairs show that the soil lead is independent of the bedrock lead, which has little variation, indicating a probable outside outside source for the anomalous soil lead in this sample array.

The higher-than-normal lead concentrations lack a certain explanation, but we propose that they may be air-borne deposits from the Roman smelting furnaces, preserved in the soil blanket. If this interpretation is correct, it may further mean: (1) The amount of soil erosion that can have taken place in the Tamuja valley since the end of Roman mining is limited; and, (2) Significant soil contamination from smelter fumes may also persist in soil for many centuries. Our 1999 and 2000 field work has included many samples taken from auger holes to help determine if the anomalous soil lead is confined to a thin layer at the surface and results of many of these analyses are expected in early 2001.

Summary

Sampling and analyses of many different environments in the Plasenzuela silver-lead mining district show that significant metals persist in the ancient mining and metallurgical wastes, and have migrated into adjacent soils, contaminated river sediments, been taken up by plants, and may have been distributed by smelter plumes to more distant soils in the area. Though Plasenzuela is a relatively small mining district, even by Roman terms, its relative simplicity compared to the enormous and complex wastes of other ancient mining districts in the Iberian peninsula make it an excellent place to begin seeking an understanding of mining and metallurgical waste behavior over extended time.

References Cited

Anderson, S., Chappelka, A.H., Flynn, K.M., and Odom, J.W., 2000, Lead accumulation in Quercus nigra and Q. velutina near smelting facilities in Alabama, U.S.A.: Water, Air and Soil Pollution, 2000, v. 118, n. 1-2, p. 1-11.

Conophagos, Constantine, 1982, Smelting practice at ancient Laurion: in The evolution of the first fire-using industries, Wertime, T.A., and Wertime, S.F., [eds.], Washington, D.C., Smithsonian Institution Press, p. 181-191.

Craddock, P.T., 1995, Early metal mining and production: Washington, Smithsonian Institution Press, 363 p.

Domergue, Claude, 1987, Términomunicipal: Plasenzuela, in Catalogue des mines et des fonderies antiques de la Peninsule Iberique: Publications de la Casa de Velazquez, serie archeologie, Fac. VIII, T. 1, p. 53-57.

Hong, Singmin, Candelone, J-P, Patterson, C.C., and Boutron, C.F., 1994, Greenland ice evidence of hemispheric lead pollution two millenia ago by Greek and Roman civilizations: Science, v.265, p. 1841-1843.

Jones, J.E., 1984, Ancient Athenian silver mines, dressing floors and smelting sites: Jour. Historical Metallurgy Society, v. 18, p. 65-81.

Nriagu, J.O., 1998, Tales told in lead: Science, v. 281, p. 1622-1623.

Pyatt, F.B., Gilmore, G., Grattan, J.P., Hunt, C.O., and McLaren, S., 2000, An imperial legacy? An exploration of the environmental impact of ancient metal mining and smelting in southern Jordan: Jour. Archaeological Science, v. 27, p 771-778.

Ramage, Andrew, Craddock, Paul, and Craddock, P.T., 2000, King Croesus' Gold: Harvard University Press, 264 p.

Roswag, Clemente, 1853, Apuntes sobre las minas de Palacios y Golondrinas, y refutacion del informe del señoringeniero Letellier: Cáceres, 108 p.

Schmidt, R.G., Ager, C.M., and Gil Montes, Juan, 1999, A study of Roman mining and metallurgy and their environmental consequences at Plasenzuela, Extremadura, Spain: in Metals in Antiquity, S.M.M. Young, A.M. Pollard, Paul Budd, and R.A. Ixer, eds., British Archaelogical Reports, Series 792, Oxford, Archaeopress, p. 234-242.

Shacklette, H.T., and Boerngen, J.G., 1984, Element concentrations in soils and other surficial materials of the conterminous United States: USGS Professional Paper 1270, 105 p.

Shotyk, W., Weiss, D., Appleby, P.G., Cheburkin, A.K., Frei, R., Gloor, M., Kramers, J.D., Reese, S., and Van Der Knaap, W.O., 1998, History of atmospheric lead deposition since 12,370 14C yr BP from a peatbog, Jura Mountains, Switzerland: Science, v. 281, p. 1635-1640.

Acknowledgements

Research grants from the National Geographic Society Committee for Research and Exploration and from the U.S. Department of the Interior, Human Resources Initiative, made the project possible by supporting data collecting trips, and paying part of the analytical costs. The U.S. Geological Survey provided analytical and salary support. Carmen Anton-Pacheco and Pablo Gumiel, of the Instituto Tecnológico GeoMinero de España, Madrid, helped us in the field and introduced us to the local scientists who gave us much assistance and made the work much more enjoyable. Our colleagues at the University of Extremadura, especially Jose Maria Fernandez Corrales, Enrique Cerrillo Martin, , Dionisia Gomez-Amelia, and Susanne Schnabel were most generous with their advice and time, and to them we are ever so grateful. Juan Carlos Casco and Marcelino Moreno Morales, Centro Piloto de Estudios y Proyectos, Ayuntamiento de Plasenzuela, gave us significant help in understanding the history, culture, and particularly the agricultural practices of our working area. We owe special thanks to Elena Aguilera Collado of the Museo Minero, Minas de Riotinto, Spain, for introducing us to the Roman metallurgical sites at Rio Tinto, and for sharing her interpretations of the mining industry in our study area. The use of library and computer facilities provided by the Xavier de Salas Foundation and the Coria Museum,Trujillo, is most gratefully acknowledged.