Wind Power

WindPower

Types of Windmills

Aeration Windmill

Aermotor Windmill The

Wind Turbine

Important

Factors

to Consider When Building A Windmill

Location

Wind Characteristics

Terrain Characteristics

Windmill Efficiency

The Purpose of

Windmill Shrouds

Electricity and Storage of

Energy

Brakes Windmills

Today

Bibliography

Types of Windmills

Aeration Windmill

This windmill will aerate a pond or pump water out of your pond or river to water your animals or garden. This windmill will pump out of a shallow (up to 15m) well.

Aermotor Windmill

They have been manufactured since 1888 and are the old standard of windmills. They will pump out of a well but will not efficiently aerate a pond or pump water out of the pond or river.The Wind Turbine

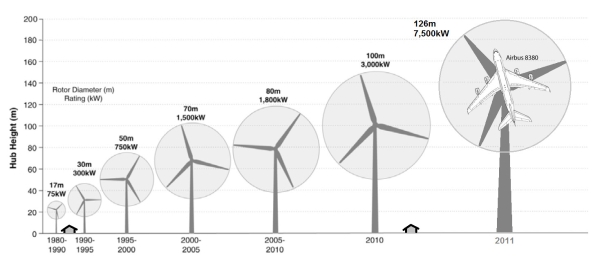

The wind turbine, also called a windmill, is a means of harnessing the kinetic energy of the wind and converting it into electrical energy. Modern low speed wind turbines seem to become more efficient as they scale up. A 3m diameter home turbine (unless in a rare ideal location) will be rather fickle and not very reliable. A 30m blade such as those in Ravehshoe Queensland are too expensive for single household use, more efficient in producing electricity but still affected by terrain effects. The 150m turbines at Mount Emerald are relatively free of ground effects and the most efficient. Kinetic wind energy turns blades called aerofoils, which drive a shaft, which drive a motor (turbine) and ar e connected to a generator.

"It is estimated that the total power capacity of winds surrounding the earth is 1 x 1011 Gigawatts" (Cheremisinoff 6). The total energy of the winds fluctuates from year to year. Windmill expert Richard Hills said that the wind really is a fickle source of power, with wind speeds to low or inconsistent for the windmill to be of practical use. However, that hasn't stopped windmill engineers from trying. Today, there are many kinds of windmills, some of which serve different functions. They are a complex alternative energy source.

There are a number of types of windmills. They are divided into Horizontal-Axis and Vertical-Axis types. Low speed horizontal-axis windmills are used for water pumping and air compressing. Southern Cros windmills are an example. Earlier windmills such as the ones in England and Holland build a couple hundred years ago are another

example.

The horizontal-axis

was invented in Egypt and Greece in 300 BCE. "It had 8 to 10 wooden beams rigged with sails, and a rotor which turned perpendicular to the wind direction" (Naar 5). This specific type of windmill became

popular in Portugal and Greece. In the 1200's, the crusaders built and developed the post-mill, which where used to mill grain. It was first used to produce electricity in Denmark i n the late 1800's and spread soon after to the U.S. In America, windmills made the great plains.

They were used to pump water and irrigate crops. During World War I, farmers rigged windmills to generate 1 kW of DC current. They mounted their devices on the tops of buildings and towers. On western farms and railroad stations, the pumping windmill was 6-16m high with a 2-3m wheel diameter"

(45)]. With 15kmh wind speed, a 2m-diameter wheel, a 60cm diameter pump cylinder, a windmill-pump could lift 200L per hour to a height of 12m. A 4m in diameter wheel could lift 250L per hour to a height of 38m.

The growth of wind-electricity in Australia was greatly peaked in the 1930's and 40's . However, in the 1970's, due to oil shortages, earlier prototypes of high-speed horizontal-axis windmills were developed. High-speed horizontal-axis types are used for many purposes, come in many sizes. These include the typical windmills on windmill farm and any other wind turbines in which the shaft turned by the aerofoils is horizontal. High-speed horizontal types may have 1, 2, 3, 4, or many aerofoils.

Low-speed types such as European ones have much larger aerofoils in relation to their height above the ground. Low speed types such as western Queensland ones are usually a pinwheel, with many small blades encircled with an outer frame like a wheel. Vertical-axis windmills were first developed in the Persians in 1500 BCE to mill corn and were still in use in the 1970's in the Zahedan region. Sails were mounted on a boom, which was attached to a shaft that turned vertically. By 500 BCE, the technology had spread to Northern Africa and Spain. Low-speed ve rtical-axis windmills are popular in Finland. They are about 150 years old. They consist of a 200L oil drum split in half. They are used to pump water and aerate land. They are inefficient.

High-speed vertical-axis windmills

include the Darrieus models. These have long, thin, curved outer blades, which rotate at 3 to 4 times the wind speed. They have a low starting torque and a high tip-speed ratio. They are inexpensive and are used for electricity generation and irrigation. There are three types, the delta, chi, and gamma models. All models are built on a tripod. The advantages to a Darrieus-windmill are that it can deliver mechanical power at ground level. The generator, gearbox, and turbine components are on the ground, instead of at the top of a tower as in horizontal-axis windmills. They cost much less to construct, because there is less material, and the pitch

of the blades does not have to be adjusted.

Another type of HSVAW's are the Madaras and Flettner types, revolving cylinder s which sit on a tracked carriage. "The motion of a spinning cylinder causes the carriage to move over a circular track and the carriage wheels to drive an electric generator" (Justus). The Savonius model, which originated in Finland in the 1920's, is a n S-shaped blade, which rotates and turns a vertical shaft. Today, these types of windmills are very popular with scientists

and their technology is being developed.

Important Factors to Consider When Building A Windmill

What to consider when building a windmill In choosing where to build a windmill, there are many important factors to consider.First is the location:

1) Available wind energy is usually higher near the seacoast or coasts of very large lakes and offshore islands. 2) Available wind energy is generally high in the central Austrsalia because of the wide expanses of level (low surface roughness) terrain.3) Available wind energy is generally low throughout eastern Australia with the exception of mountain passes but higher on the southern and western coasts

Wind Characteristics

Also important to consider the wind characteristics where you are going to build: 1) the mean wind speed (calculated my cubing the averages and taking the mean of the cubes) and its seasonal variations. 2) The probability distribution of wind speed and of extreme winds. The mean wind speed must be high enough, and the distribution must be so that all the data points are very similar.3) The height variation of wind speed and wind direction. Wind cannot be too high or too low in relation to the ground or it is too difficult to harness.

4) The gustiness of the wind field in both speed and direction. Gusty winds greatly affect the power output of the windmills and are usually harmful.

5) The wind direction distribution and probability of sudden large shifts in di rection. The wind must be

unlikely to suddenly shift direction. It must blow in the same general direction.

6) the seasonal density of the air, and variations of density of the air with height. The denser the air, the worse it will be for windmills.

7) Hazard conditions such as sandstorms, humidity, and salt-spray, which are bad for windmills.

8) Trade winds in the subtropics, and the channeled wind through mountain passes are especially beneficial to windmills.

Terrain Characteristics

Once a suitable location is found, the wind is analysed extensively, and the criteria is met, there are still more requisites.- 1) The terrain upon which the windmills are built must be relatively flat. The elevation difference between the turbine site and the terrain is no larger than 60 meters over a 12-km radius. You may have seen windmills such as those in Ravenshoe, Far North Queensland on little hills, but this is because the requirement is met. The hill may be the only one in a mountain pass

- 2) All hills must have small height to width ratios: h:l must be < 0.016.

- 3) The elevation difference between the highest and lowest point

must be 1/3 or less of the height difference between the bottom of the

rotor disk and the lowest

point in the terrain strip.

The surface roughness of the terrain upon which the windmill is to be built must be low. If it varies by more than 10%, this is no good. The terrain must be smooth, and consistently so. A rough surface has more of a negative effect on the wind than a smooth surface. There is a value n, called, which is assigned to the terrain in terms of its roughness. This value is used to calculate the height of the windmill. For instance, over the sea, the index location, n is 0.14. Over rough inland country, n is 0.34.

Wind Mill Efficiency

Windmills are turbines. The two names can be used synonymously. Turbines are a means of harnessing the a fluid's power (the wind) by converting the kinetic energy of the fluid (the wind) into mechanical power (the rotating shaft) When the shaft of a w indmill is hooked up to a generator, electrical energy can be formed. The generator can be used to produce either DC or AC current. Generators that produce DC can be connected to batteries, an inverter to produce AC, or to power DC loads.Some generators are connected to heating coils. Generators that produce AC can be hooked up to AC motors such as water pumps. Windmills are NOT efficient. At the very most, a windmill can extract only 16/27ths of the kinetic energy from the wind. This is called the Betz Limit and it can be mathematically proven through calculus. Most of today's windmills extract about 30 perc ent of the wind's energy.

The Southern Cross farm windmill can only extract 10%. An important equation used to find the wind power density, how much power is available per square meter is the equation

P = .5 pu³

where P is the wind power density in W/m2, p is the density of the air, and u³ is the cube of the wind velocity.

An equation for the power available is :

where p is the kinetic energy density J/m³, V is the velocity of the wind, A is the cross sectional area of the wind on the turbine.

The equation for determining the power of the shaft, (which is

less than the final power output, since gear trains and generators cause

power to be lost) is as follows:

Cp = P(0.5 p V ³ (D2)/4

Where Cp is the power coefficient (Power of shaft), p is the air density,

D is the rotor diameter, V is the velocity of the wind and P is the net

power output.

Also Cp = P available/P turbine

The power available is a function of elevation. At ground level, 100% of

the power is available. At 30m, 97% is available. At 1500m , 86% is available.

The Purpose of Windmill Shrouds

Some turbines are shrouded like jet engines. The shroud is a way to channel the wind.An equation for the power harnessed by a shrouded wind turbine is:

P(Pe) = ( QT ((p + (k) where P is the power,

Pe is the power extracted, ( is the turbine efficiency, QT is the

volumetric flow rate of air on the turbine, (V/A), ((p + (k) is the change

in pressure energy between the inlet and the exit of the wind turbine, and

k is the cane in kinetic energy of a unit volume of air that passes

through the machine.

Shrouds concentrate and diffuse the wind as it passes through a horizontal access wind-turbine. They reduce the turbulence of the wind and "direct it".

The advantages of shrouds, as told by Cheremisinoff (pg. 61 of Fundamentals of Wind Energy), are:

a ) the axial velocity of the turbine increases, meaning that smaller rotors can operate at higher revolutions,

b) the shroud can greatly reduce tip-losses, and

c) the aerofoils would not have to be rotated in a direction parallel to the wind if the wind-direction changed.

The cut in speed is the lowest wind speed below which no usable power can be produced by a wind turbine. This means that the wind must be fast enough to move the aerofoils to drive the shaft to create enough power, after much is lost, so that the end amount of power isgreater than zero.

Rated power is the maximum power output of a turbine, which is dependent on a number of factors, especially the generator. In calculating the height of the windmill, it is important to keep in mind that the windmill must be high enough to be above obstructions. The wind velocity decreases as one approaches the surface. That means that the higher you build, the better chance there will be that the wind speed is higher, however, you must find the perfect medium--there are often more variables as you increase in

altitude.

In calculating how high a windmill should be the following

equation is used: V1/V2 = (H1/H2)n,

Where V1 is the wind speed at the highest point of the highest blade, V2 is the wind speed at the lowest

point of the lowest blade, H1 is the height of the highest point, and H2 is the height of the lowest point. n is the index location of the site, a value that measures the roughness of the terrain.

The support of the windmill is generally made out of steel. The windshaft is the shaft which carries the windwheel or aerofoils. It is turned as the aerofoils turn. It is made of steel or wood.

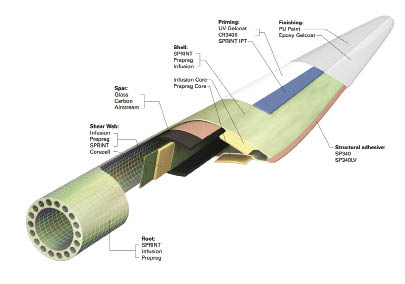

Aerofoils are the blades on a windmill. They can be made out of any material. They were first made of wood or wood composites. Steel was used after that. Aluminum is used in the Darrieus windmills because it is much stronger. Unfortunately, Aluminum fatigues quicker. Some windmills use fiberglass blades. New materials such as strong alloys are being used in today's windmills experimentally.

It is important that the blades have a large lift force and a small drag force.

The lift force is the force needed to bend the flow of the (fluid) air. It is the force perpendicular to the stream of the air.

The drag force is the force parallel to the stream.

The aerofoil must be able to develop a lift force at least 50 times greater than the drag. Torque acts on the aerofoil with a vector from the center of rotation away.

Other forces that act on the blades of windmills are wind shears, wind gusts, which push on the aerofoils, gravity, a pull towards the earth, and shifts in the direction of the wind. Shifts in the direction of the wind are often accounted for by having a small blade, called a tailvane, on the backside of a windmill. The wind blows on a flat side of the tail, which is oriented differently from the aerofoils. Then, the aerofoils can be rotated to face into the wind. If the wind is blowing in the direction of this tail instead of the direction of the aerofoils, the tail rotates a shaft, which rotates the whole windmill in the proper direction so as to orient it towards the wind.

Wind gusts can greatly affect a windmill. A turbulent gust is a gust greater than two minutes with a certain mean wind speed. Gusts are analyzed extensively, with magnitudes, one fo r the lull speed, which is the wind speed of a negative gust amplitude, and the peak speed, which is the wind speed for a positive gust amplitude.

The gust amplitude is the difference between the largest speed in the gust and the mean speed.

The gust duration is the time from the beginning to the end of a gust.

The gust frequency is the number of positive gusts, which occur per unit time.

The gust formation time is the time it takes from the beginning of a gust to the time it attains the peak gust spe ed.

The gust decay time is the time it takes for the gust the end after it reaches its highest amplitude.

There is quite a bit of terminology with aerofoils.

The angle of the surface to the fluid flow is the angle of attack, alpha. The angle of attack must be just right. If it is too great, the lift will dramatically decrease and the drag will increase, st alling the windmill. At rest, (when the windmill is not in operation), the angle of attack is 85°. When in motion, the angle of attack is anywhere from 2-10 degrees. Newer and more advanced windmills have an angle of attack in the upper end of this range.

The pitch angle, ß is the angle between the chord of the aerofoil and its plane of rotation. The pitch angle can be adjusted.

Solidity is the ratio of the blade width (at widest point) to the distance between the centers of the blades. A typical "pinwheel Southern Cross windmill" might have a ratio of about 1:1, because the blades are very narrow and very close together, whereas a new two-bladedaerofoil would have a ratio of about 0.03. There is a transfer of work between the wind stream and the moving blade. In order for this transfer to be efficient, a typical blade is usually 1/4 the width of its length. (If the blade is 3m long, it will be 750mm wide at its widest point).

Aerofoils come in many shapes. Some blades are made a little wider than this ratio, because it is easier to start such a windmill. However, blades like this aren't as efficient. No matter what the shape, "most have a blunt nose and a finely tapering tab le" (Calvert). A flow must be able to follow the curved surfaces of the aerofoil without being separated. The mass flow rate is given by the equation:

m = p Vb A

, where p is the air density, Vb is the air speed at the blades and A is the area.

The number of blades on a windmill varies. There are many different types of windmills. The following equation helps figure out how fast the a certain-bladed windmill

will rotate in relation to windmills with different numbers of blades:

Speed of windmill = 1 / sq. root of number of blades

The aerofoils of a four bladed machine rotate 71% as fast as that of a 2 bladed machine. A six bladed machine rotates at 58% and an 8 bladed machine rotates at 56% as fast as a 2 bladed machine.

Electricity and Storage of Energy

As mentioned previously, the generators in a wind turbine can convert the mechanical energy produced by the rotation of the shaft into electrical energy, DC. From there, some windmills have synchronous inverters, complex electronic devices which convert the DC generated by the turbines into AC. This is an expensive option. There is a loss of power as well through its processes. Others have induction generators, which produce AC current without a synchronous inverter and less power loss. The energy extracted from the wind and converted into mechanical energy then electrical energy by the generator must be stored, since it is not used generally used all at once. It is important to keep a surplus of energy for usage when the wind is not blowing fast enough, despite the corrections that can be made in the pitch of the aerofoil blades and when the windmill is out of service or the demand is especially high.Storing the wind's energy effectively is the key to its long-term use. Windmills used as water pumpers or air-compressors can pump excess water, hydrogen or air into reserve tanks. Today, there are a number of ways to store the wind's energy. Windmills are used to charge Electrolyte batteries. Lead-acid or Lead-cobalt car batteries are commonly used as well. However, batteries may be expensive and inefficient--they may lose 10-25% of the energy stored in them.

Nickel-Iron, Nickel-cadmium, and zinc-air cells are often used as well. These tend to be more efficient. Some windmills are now using organic electrolyte batteries such as CuCl2, Ni Cl2, and NiF2 batteries as well as sodium-sulfur batteries, which operate at high temperature, are used. Although uncommon and still in experimental phases, some energy is stored not by being converted directly into electrical energy, but rather by being stored as thermal or electromagnetic energy,

Sound Fluids are elastic. Pressure waves are constantly being created and propagated by the aerofoils and the turbine as a whole (entire components excepting the support). We can hear them in the sound given off. The sound intensity is directly proportional with the speed of the windmill.

The frequency of the waves is directly proportional to the angular speed of the blades on the rotor. The flutter you hear has aerodynamic and elastic properties. The higher speed the aerofoils are, the louder the sound a nd the louder the flutter they will make, as more pressure waves are being created and propagated. The generators are noisy. They often confuse birds and cause them to fly towards the turbine.

Windmills can be very noisy. A 300 kW turbine at 1 mile away has a dB level equal to a traffic light 100 feet away (Gipe). Windmill sound levels are regulated.

The sound level must be kept under 46 dB in a residential area. Wind turbines can cause interference, disturbances with TV and radio reception (ghost images on TVs), affect microwaves and disrupt satellite communication. These problems are currently being resolved. Many have already been fixed. There is also a .009 probability of a bird or insect being struck by the blades. Windmill makers must use artificial sound or florescent paint or scents to scare away flying creatures.

Brakes

Mechanical brakes are used to hold windmills at rest when they are not needed, are not functioning, or are under repair. Greek windmills used sticks or logs jammed into the ground to keep the windmill stopped, but modern brakes are more sophisticated. Many windmills today use airbrakes like those used in planes. Other windmills have rope brakes.Ropes connected to the aerofoils are simply pulled and tethered to a post to keep the aerofoils from turning. The torque on a rope brake can be calculated by the equation :

(M-m)(R2 + r)g

Windmills

Many windmills are used today. They are used to heat water, refrigerate storage buildings or rooms, refrigerate produce, dry crops, irrigate crops, heat buildings, and charge batteries for tr actors on farms . Ever since the energy shortages of the 70's, the growing concern of pollution due to the burning of fossil fuels and the depletion of natural resources, windmills have been greatly studied and developed. Today, Sandia National Laboratories, Alcoa, GE, Boe ing, Grumman, UTC, Westinghouse, and other scientists are researching and developing Darrieuses and new types of windmills. Today, windmills are used to operate sawmills and oil mills in Europe. They are used in mining to extract minerals, to pump water , to generate electricity, and to charge

batteries. "Windmills have been used on buoys moored far out in the ocean, the power being used for the collection and transmission of oceanographic and weather data. They also work in deserted places as an aid to radio and telephone communications and they are used to work navigation lights on isolated hazards" (Calvert 77).

The Future will likely bring bigger and better things for the wind turbine. Many new wind turbine models are being built. The wind turbine holds much promise for energy production in the years to come.

Bibliography

Calvert, N. G. Windpower Principles: Their application on the small scale. London: Charles Griffin and Co., Ltd., 1979. Cheremisinoff, Nicholas P. Fundamentals of Wind Energy. Ann Arbor: Ann Arbor Science Publishers, Inc. 1978.Gipe, Paul. Wind Energy Comes of Age. New York: John Wiley and Sons, Inc. 1995.

Hau, E., J. Langenbrinck, and W. Palz. Large Wind Turbines. Berlin: Springer-Verlag, 1993.

Hills, Richard L. Power From the Wind: A History of Windmill Technology. London: Cambridge University Press, 1994.

Justus, C. G. Winds and Wind System Performance. Philadelphia: The Franklin Institute Press, 1978.

Naar, Jon. The New Wind Power. New York: Penguin Books, 1982.

Taylor, R. H. Alternative Energy Sources for the Centralized Generation of Electricity. Bristol, England: Adam Hilger, Ltd. 1983.