Hydro-electricity and RAM Pumps

Hydro-electricity and RAM Pumps

What is hydro-electricity?

Vital

Factors for Hydro-electric Energy - "Flow and Head "

How much

electricity will you get?

Domestic-size

power plants - Micro-hydro

Pumped Hydroelectric Storage in Australia - Kidston

Queensland

RAM

Pumps - use Water to Pump Water...

What is hydro-electricity?

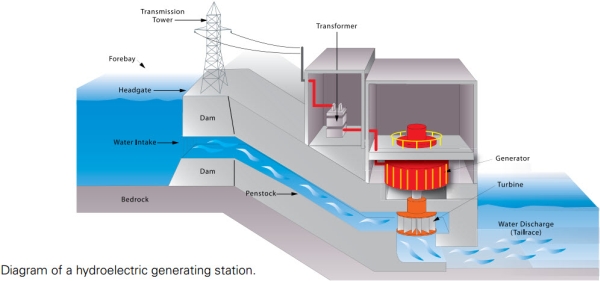

Hydro-electric power plants convert the kinetic energy contained in falling water into electricity.The energy in flowing water is ultimately derived from the sun, and is therefore constantly being renewed. Energy contained in sunlight evaporates water from the oceans and deposits it on land in the form of rain. Differences in land elevation result in rainfall runoff, and allow some of the original solar energy to be captured as hydro-electric power

Hydro power is currently the world's largest renewable source of electricity, accounting for 6% of worldwide energy supply or about 15% of the world's electricity.

The majority of these power plants involved large dams which flooded vast areas of land to provide water storage and therefore a constant supply of electricity. In recent years, the environmental impacts of such large hydro projects are being identified as a cause for concern. It is becoming increasingly difficult for developers to build new dams because of opposition from environmentalists and people living on the land to be flooded.

The Vital Factors for Hydro-electric Energy - "Flow and Head "

The two vital factors to consider are the flow and the head of the stream or river.The flow

is the volume of water which can be captured and re-directed to turn the turbine generator

The head

is the distance the water will fall on its way to the generator.

The larger the flow –i.e. the more water there is, and the higher the head – i.e. the higher the distance the water falls

– the more energy is available for conversion to electricity.

Double the flow and double the power, double the head and double the power again.

How much electricity will you get?

The key equation to remember is the following:

Power = Head x Flow x Gravity

where power is measured in Watts, head in metres, flow in litres per second, and acceleration due to gravity in metres per second per second.The acceleration due to gravity is approximately 9.81 metres per second per second – i.e. each second an object is falling, its speed increases by 9.81 metres per second (until it hits its terminal velocity).

Therefore it is very simple to calculate how much hydro power you can generate. Let’s say for example that you have a flow of 20 litres per second with a head of 12 metres.

Put those figures in the equation and you will see that:

12 x 20 x 9.81 = 2,354 Watts

Efficiencies of around 70% can be expected which is to say that 70% of the hydraulic energy of the flowing water can be turned into mechanical energy spinning the turbine generator. The remaining 30% is lost. Energy is again lost in converting the mechanical energy into electrical energy (electricity) and so at the end of the day you can expect a complete system efficiency of around 50-60%. In our previous example where 2.3kW of power was available – we can therefore expect to generate around 1.1-1.4kW of electricity.High head hydro-electric commercial power plants

Plants can generally be divided into two categories. "High head" power plants are the most common and generally utilize a dam to store water at an increased elevation. The use of a dam to impound water also provides the capability of storing water during rainy periods and releasing it during dry periods. This results in the consistent and reliable production of electricity, able to meet demand. Heads for this type of power plant may be greater than 1000 m. Most large hydro-electric facilities are of the high head variety. High head plants with storage are very valuable to electric utilities because they can be quickly adjusted to meet the electrical demand on a distribution system.Low head hydro-electric commercial power plants

are power plants which generally utilize heads of only a few meters or less. Power plants of this type may utilize a low dam or weir to channel water, or no dam and simply use the "run of the river". Run of the river generating stations cannot store water, thus their electric output varies with seasonal flows of water in a river. A large volume of water must pass through a low head hydro plant's turbines in order to produce a useful amount of power. Hydro-electric facilities with a capacity of less than about 25 MW (1 MW = 1,000,000 Watts) are generally referred to as "small hydro", although hydro-electric technology is basically the same regardless of generating capacity.Domestic-size power plants - Micro-hydro

A low head site has a head of below 10 metres. In this case you need to have a good volume of water flow if you are to generate much electricity.

A high head site has a head of above 20 metres. In this case you can get away with not having a large flow of water, because gravity will give what you have an energy boost.

Pumped Hydroelectric Storage in Australia - Kidston Queensland

The Australian Renewable Energy Agency is supporting a feasibility study into the construction of a pumped storage hydroelectric power plant at the disused Kidston Gold Mine in North Queensland.

Located 280km north west of Townsville, the project has the potential to generate up to 330 MW of rapid response, flexible power for delivery into Australia’s National Electricity Market.

Electricity generation in a pumped storage system works much like a conventional hydroelectric scheme:

- in periods of high demand, electricity is generated by releasing water from an upper reservoir through reversible turbine-generators and into a lower reservoir.

- However, unlike a conventional hydro scheme, water is not then discharged from the lower reservoir but pumped back to the upper reservoir during off-peak hours using electricity from the grid.

This process is similar to the Wivenhoe Pump Storage scheme and Snowy’s Tumut 3 scheme.

The Kidston Project would be a highly efficient form of large-scale energy storage that helps to manage the growth of intermittent forms of renewable energy such as solar and wind.

Intermittent generation can therefore be stored and dispatched to the grid during periods of high demand.

The Kidston Project will be the first in the world to use two disused mine pits for hydroelectric power generation.

The use of existing infrastructure from the old mining operation is also expected to significantly lower construction costs.

Knowledge gained from this project may be used at other mine sites to generate and store renewable energy.

Like other hydroelectric power plants, the facility will offer rapid response to the demands of the grid, helping to restart other generators and the electricity grid within seconds in the event of network shutdown.

Genex estimated the power facility will cost $282 milion and aims to commence construction in 2017, with first year of operation scheduled for 2019.

The project will contribute to stability of the electricity grid by combining renewable energy generation with large-scale energy storage capability. It is also expected to help meet the growing demand for electricity at peak times in Queensland, as well as help alleviate the state’s peak power prices.

It may be possible as pumped storage hydrodevelops , to recharge the system using excess alternative power , for example from solar arrays. this would overcome the limitations of large scale battery storage and provide a profitable use of excess alternative energy.

A RAM pump uses Water to Pump Water...

Steps in the RAM pump cycle...

- water, enters the steel drive pipe and flows through it by gravitation until it reaches the RAM, passes through the RAM and out through the pulse valve into the waste drain.

- as the water flows, its velocity increases until the pulse valve is no longer able to pass the volume of water flowing: at this point the pulse value is suddenly closed.

- Since outlet is now closed, the flow of water suddenly stops.

- this produces a concussion of more or less severity in the body of RAM according to the height and distance from which the water is flowing.

- the result of this concussion is that a portion of the water in the body of the RAM is forced upwards through the delivery valve into an air cylinder.

- at the same time the recoil allows the pulse valve to return to its original open position.

- so the outlet is reopened,

- the water which was brought to rest by the closing of the pulse valve starts flowing again through the RAM until it acquires the necessary velocity to raise the pulse valve a second time, closing the outlet, producing a concussion and forcing more water into the air chamber through the delivery valve.

- the water, which is forced into the air chamber, finds its way through a pipe, known as the 'rising main', to the place where it is required for use with a continuous flow being maintained so long as the RAM remains working.

The fall of water necessary to work a RAM may be as low as 500mm (20 inches) and with such a fall, water may be raised to 18m (60 feet). With higher falls, such as from 2m (6.7 feet) to 7m (23.3 feet) and over, water can be raised to upwards of 300m (1000 feet) or more in height and distance is more or less unlimited: several of our ram installations pump to over 5km (3.13 miles).

- due to the action of the RAM, unless the conditions are unusually severe, and provided the RAM is kept working and the water keeps flowing,, the RAM will be unaffected by changes in temperature especially low temperatures which might cause a conventional system to 'freeze up' unless some form of heat is provided.

- the waste valve can be a spring-operated normally-open valve that closes when the flow velocity generates sufficient drag. t

- the water in the drive pipe, which is long and rigid (steel pipes will generate higher pressure than pvc), has gathered significant momentum (p=m*v) by that time.

- when the valve closes, that momentum generates pressure, slamming open the check valve and compressing the air in the reservoir.

- the check valve closes again, the compressed air expands, pushing water up the delivery pipe. The waste valve reopens and the process repeats.

- the air reservoir stores the energy, absorbs the pressure pulses, and provides continuous flow at the delivery pipe.

- without the air, every time the waste valve closes, the two water columns are in direct contact, one at full speed, the other at rest.

- that will cause either large pressure peaks (when they meet head on), or large movement of the pump. At 30,000 times a day, they may not last very long.

- the fundamental difference between a pump with air reservoir and one without is the efficiency: without reservoir, energy is transferred by a perfectly inelastic collision: the water in the drive pipe and the water in the delivery pipe have the same velocity after the collision.

- not only is that the collision where most energy is lost, the mass in the drive pipe is also the largest mass, and will keep most of its energy after the collision.

- with a reservoir, most of the energy of the drive mass is transferred to the reservoir, and all that energy is used to pump the water in the delivery pipe.

source: http://www.reuk.co.uk/wordpress/hydro/calculation-of-hydro-power/

https://www.physics.ohio-state.edu/~kagan/phy367/P367_articles/HydroElectric/hydroelectric.html